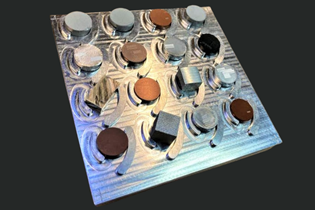

Full chemical characterization for most additive manufacturing (AM) metals requires at least three different analytical techniques, specialized skills and significant time and lab space to properly execute. Instead, a new desktop instrument rapidly quantifies the metallic, trace and light elements in a matter of minutes. Its user interface is as easy as a smartphone so it does not require chemistry expertise to prepare a sample, analyze its components or create chemical maps.

Rapid chemical characterization accelerates new material development, quality control processes for virgin and reused feedstock, and failure analysis for final parts. The new instrument combines an innovative, dual-laser ionization source (laser ablation laser ionization) with time of flight (TOF) mass spectrometry.

This webinar will describe this new analytical technique, demonstrate the instrument's intuitive user interface and explore results of several case studies.

Agenda:

- The importance of chemical characterization and the current state of analytical instruments

- Introduction to laser ablation laser ionization TOF mass spectrometry

- Demo of the instrument's intuitive user interface analyzing AM materials

- Results of case studies for metal powder quality control and build failure analysis