Hear first-hand from General Pattern, an injection molder with in-house tooling services and over 100 years of experience, is addressing the labor issue, increasing toolmaking capacity and helping OEMs accelerate product development by integrating Mantle's 3D printer to automate its toolmaking processes.

In this webinar, General Pattern will share its journey with additive manufacturing and why it is implementing metal 3D printing to automate its toolmaking processes. The webinar will also include an overview of Mantle's 3D printing technology for toolmaking and case studies from injection molders, toolmakers, contract manufacturers and OEMs that have deployed Mantle. Attendees will learn how organizations use metal 3D printing to significantly reduce tooling lead times and costs, accelerate product development and solve labor challenges — all while producing better tools that incorporate conformal cooling.

Agenda:

- Hear from General Pattern on their additive manufacturing journey and why they invested in Mantle technology

- Review case studies of how General Pattern reduces tooling lead times and addresses skilled labor shortages with Mantle's technology

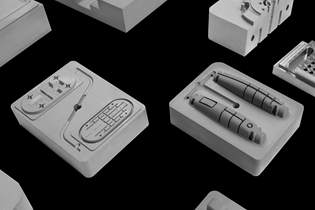

- Learn about Mantle's unique technology to print steel tooling with the accuracy, surface finish and feature detail required for injection mold tooling and other precision tooling

- Review case studies of how other manufacturers have automated their toolmaking processes with Mantle's technology

About Mantle:

Mantle has developed the only metal 3D printer built for precision tooling. Mantle automates the production of precision tooling and delivers the accuracy, finish and steel properties required for demanding tooling applications. Tools made with Mantle have molded millions of parts while reducing lead times, cutting costs and solving labor shortages.

About General Pattern Company:

General Pattern Company (GPC) is a full-service plastic manufacturer, founded on strong relationships and driven by innovation. GPC’s comprehensive offerings include in-house tooling, additive manufacturing, injection molding, urethane casting, foam molding, RIM, vacuum-forming, fiberglass and in-house painting/assembly. The extensive offering under one relationship is the difference it offers to its customers.