Options for Finishing and Postprocessing Metal 3D-Printed Parts

There is a host of technologies available for finishing and postprocessing your AM parts. This column identifies options beyond machining.

So, is machining the only way to finish your metal part after additive manufacturing (AM)? You might think so from everything you see and read, but there are countless other postprocessing techniques to improve the surface finish and dimensional integrity of your part. Besides, if you have to machine your AM part, you will likely need fixtures and jigs to orient and hold your part, especially if it is a complex organic shape. You will also need to establish datums and references on the part once it is removed from the build plate so that you know how to orient and align it. In short, doing all of this extra work to machine your AM part will quickly undermine all of the benefits and advantages of using AM in the first place.

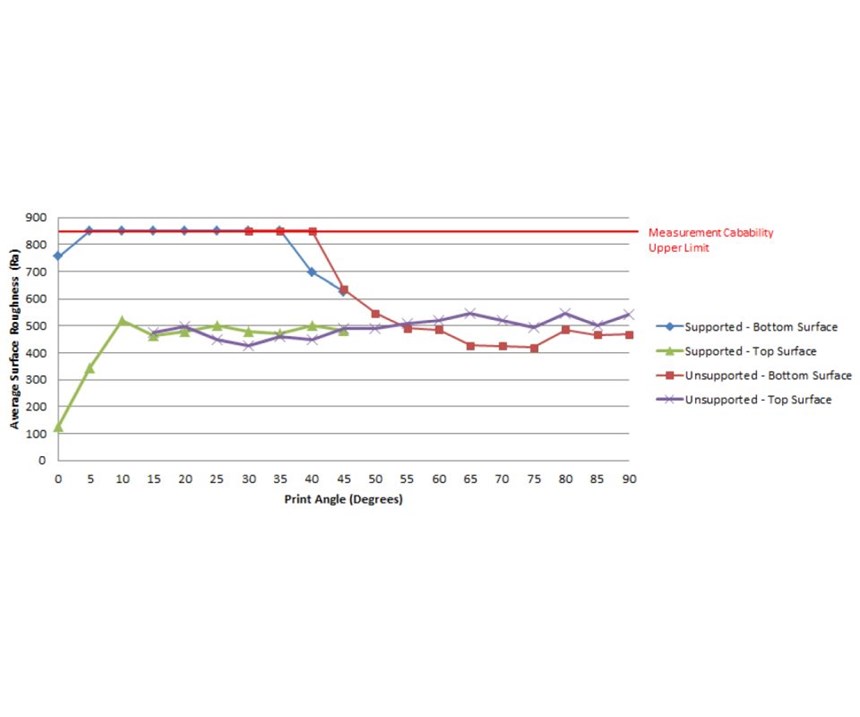

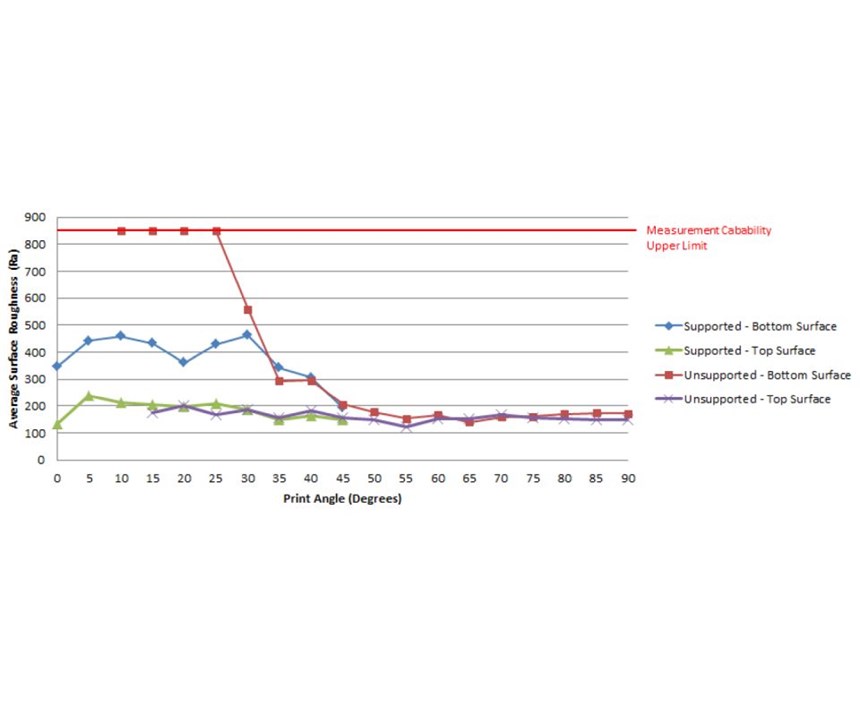

The big challenge with metal AM parts is that they are not “smooth” when they come off the build plate. The close-up of the lattice structure in Figure 1 is a great example of this. Partially melted powder particles adhered to the part, stair-stepping effects of the layer-by-layer process, tessellation of the 3D solid model and differences in up-skin and down-skin surfaces all contribute to surface roughness as I discussed in my October column. Smoothing out these rough edges and surfaces adds time and cost for postprocessing too and is critical for meeting specifications and tolerances, especially mechanical properties and fatigue life.

As it turns out, there is a host of technologies available for finishing and postprocessing your AM parts. In fact, it is the same set of technologies that you might use to finish any metal part. AM does not rewrite the rules or redefine the law of physics, nor does it negate the requirements that must be met in order for the part to fly on an airplane or be implanted into someone’s hip, for instance. Tolerances still have to be met, mechanical properties still have to be strong enough and costs need to be competitive, just like any other manufacturing process.

So, what are popular postprocessing technologies for AM right now? Media blasting with abrasive materials such as sand, grit and ceramic beads is an easy start and a simple way to reduce surface roughness, but it can be labor intensive and hard to achieve a uniform and precise finish on the entire part. Likewise, shot peening improves surface finish (see Figure 2), and it has the added benefit of improving the mechanical properties on the part’s surface through the plastic deformation that occurs during the process. Burnishing can also be used to accomplish this in specific regions on an AM part (versus peening the entire part with shot material).

Shot peening is a cold-working process, and companies offer laser peening as an alternative. Interestingly, it is not the thermal effects of the laser that do the work; it is the mechanical effects of the shock wave from the laser pulse that cause plastic deformation and harden the surface. In fact, researchers are starting to combine different lasers into one AM process—use one laser to melt the powder layer-by-layer to fabricate the 3D part and a different laser(s) to do micromachining and surface finishing. It makes sense to me.

Vibratory finishing, tumbling (barrel finishing, for example) and centrifugal finishing (harperizing, for example) are also good ways of smoothing out surfaces without needing special jigs or fixtures. Like media blasting and shot peening, these processes work well for finishing external surfaces, but accessing internal surfaces and channels can be challenging. To accomplish this, surface-finishing techniques like abrasive flow machining (e.g., extrude hone) use a viscous fluid containing abrasive particles to deburr and polish internal surfaces and pathways.

Electrochemical polishing or etching provides an alternative to abrasive polishing. It uses a chemical etchant stimulated by electrical current to smooth and treat the internal and external surfaces of a metal part. The process is relatively inexpensive and controllable, but it requires careful handling of the etchant and waste products.

Polishing and superfinishing processes can also be used to finish metal AM parts. Isotropic superfinishing, for instance, is starting to garner a lot of attention in the AM community given its ability to smooth surfaces and enhance their properties (e.g., corrosion, wear resistance) at the same time.

I am sure that I have left out several options, but I wanted to give you a sense of what the AM community is currently using and investigating for postprocessing and surface finishing. If you have a better idea or a new postprocessing technology, please reach out and share it. Just keep in mind that it needs to be cost-effective, fast, controllable, repeatable and work well for internal and external surfaces. The process should not require any special fixtures, jigs or tooling, and setup (and clean up) time should be minimal whether it is for a single AM part or hundreds (or thousands) of them. The AM community is “all ears” when it comes to improving downstream operations so that it can maintain its “complexity is free” mantra.

Related Content

3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

Read MoreHow to Organize for Additive Production: AM Radio #42

Tim Simpson and Peter Zelinski discuss the next steps for succeeding with AM: After technical and process successes come the cultural, organizational and even costing considerations associated with this mode of manufacturing.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read MoreAM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read MoreRead Next

3D Printing with Postprocessing in Mind

3D printing requires different finishing considerations than traditional manufacturing. One expert offers do’s and don’ts for approaching the finishing of additively manufactured parts.

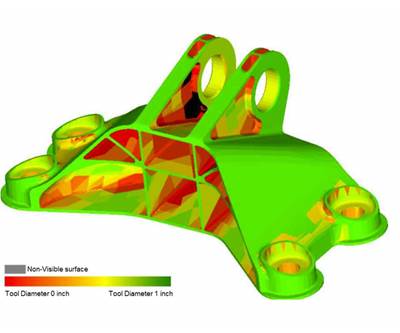

Read MoreCan My Machine Tool Access My Support Structures?

Analyzing the machinability of support structures opens a new way of thinking about optimal build orientation.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More