The Harsh Realities of Additive Manufacturing

Now is the time to start talking about what is really holding back additive manufacturing.

In many ways, additive manufacturing (AM) is a bright spot in the ongoing pandemic. The ability to rapidly iterate on design ideas or locally manufacture goods on demand with minimal tooling are two distinct advantages of AM over more conventional means of manufacturing. Unfortunately, we continue to encounter the all-too-familiar limitations of AM technologies, especially when it comes to fabricating metal parts. I can’t sugar coat it any more — time to dive into the harsh realities of AM to shed light on where the real work is needed to industrialize AM.

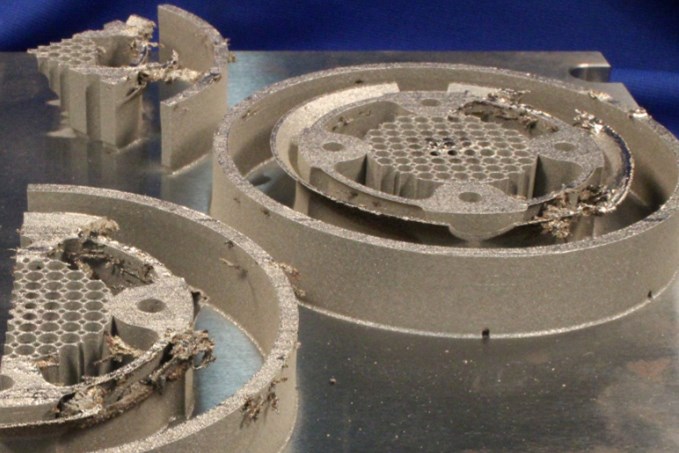

An image of one of seven build failures of a piston crown that we were trying to additively manufacture in stainless steel using laser powder bed fusion. Photo credit: Penn State CIMP-3D

First and foremost is cost. The material feedstocks are significantly higher for AM. The 5X-10X difference that you see in metallic powder feedstock compared to bar stock of the same material, for instance, makes it challenging to make a compelling business case for many metal AM parts. This is just one of many reasons why lightweighting and other design for AM (DFAM) methods are so important when adopting AM as we will discuss in the coming months.

Machine cost is also a factor, although the hourly cost to run many AM systems is now par with machining centers, for instance; however, the build time is what gets you. Additively manufacturing metal parts with laser powder bed fusion, for instance, can easily a day or two, and large, complex components may take upwards of a week or more. Multiply that amount of time by the hourly machine rate, and you will find that the operating cost for a laser powder bed fusion system to make a metal AM part can easily kill a promising application.

This brings us to the next major shortcoming, which is build speed; a big problem for many AM technologies. Granted, new laser powder bed fusion systems come with multiple lasers, which does bring the build time down substantially, but the hourly machine rate ends up being much higher given the high price tags on multi-laser systems. Sure, alternative AM technologies like directed energy deposition, binder jetting, or multi-jet fusion may offer faster build speeds, but then you encounter tradeoffs with material availability, feature resolution, post-processing, and part performance to name a few.

To make matters worse, quality can also be an issue thanks to the layer-wise fabrication that so many tout as AM’s big advantage over traditional manufacturing methods. This can lead to dimensional integrity issues, added surface roughness, and even anisotropy in some AM parts depending on the technology used. These challenges are compounded by the disconnectedness of many AM software tools for design, analysis, simulation, and build prep—not to mention the dreaded STL file format, which forces an approximation on your geometry that leads to further inaccuracies in curves and surfaces as they are tessellated and replaced by a bunch of triangles. Sadly, this is the reality that we still have to deal with 30 years later. Thankfully, progress is being made to integrate AM software tools and improve file formats, but adoption lags given the challenges with upgrading or switching software systems within a large corporation.

A related issue is the size of the part that can be made with AM. While meter × meter × meter laser powder bed fusion systems are in development, large volume builds may necessitate using a different AM process, which again may limit material availability, feature resolution, etc. This requires knowledge of multiple AM processes and their limitations, which means continuous learning to stay apace with the changing technology. Unfortunately, Manufacturing spends the least to train and educate their workforce. Based on the data I recently saw, Manufacturing spends about half of what Healthcare/Pharma does to educate their workers, one-third of what Finance/Insurance/Real Estate spends on theirs, and only a quarter of what Software/Information/Telecom spend on their employees. How on earth will any manufacturing company keep up with the latest technology advances if they are not continuing to keep their employees educated? Training is important and another topic we’ll discuss more in the future.

Knowledge of AM capabilities is only one piece of the puzzle. There are new design tools for AM that engineers must learn. Meanwhile, design allowables for AM materials are limited and/or are not being readily disclosed by companies that have made the necessary, and often significant, investment in developing them. Many standards for AM are still lacking as well. Yes, there has been a flurry of activity in the past couple of years, but keeping pace and reconciling the differences among all of the new (and emerging) standards is a challenge for anyone in the field. This makes material and process qualification and part certification for AM an expensive proposition, yet companies are doing it and finding ways to bring products to market.

So, there is hope, but it is also hard not to overpromote these successes given how rare they really are. Unfortunately, the harsh realities remain, and it is time to shine a light on them as they do not receive enough attention. I mean, who wants to read stories of the seven times your build failed or why post-processing doubled the cost and lead-time of an AM part? Complexity is free when it comes to AM, right? No, not at all, as any seasoned AM engineer will tell you — you just have to get beyond the hype and be willing to learn (and share) the real “nitty gritty” details of AM. Those are the conversations and stories that I enjoy most, actually, and I invite you back next month as I start to share our AM misadventures!

Read Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More