Product Removal Module Is a Multitasking Machine Tool Tailored to AM

An automatic bandsaw removes the parts and a milling cycle refurbishes the plate for the next build.

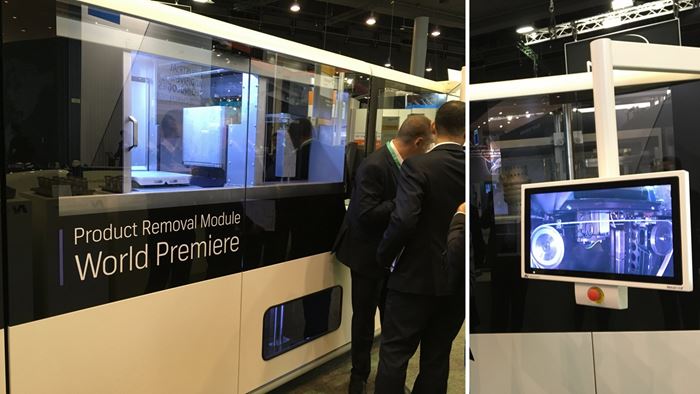

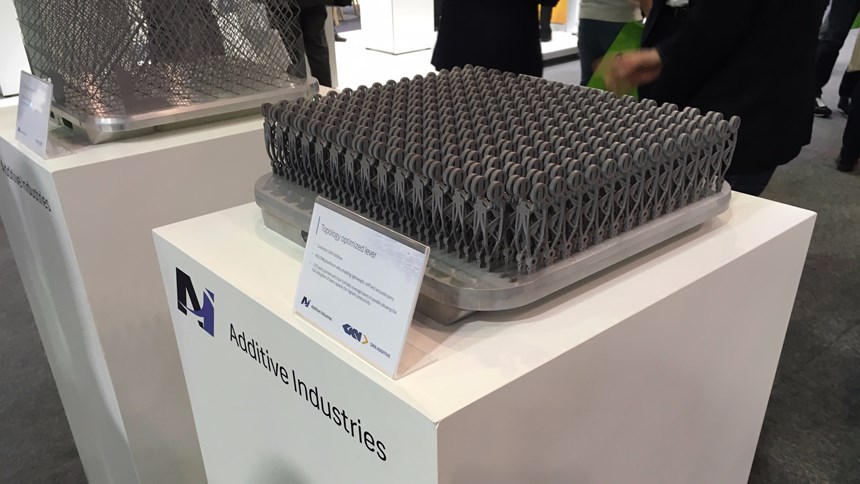

Additive Industries (which recently opened a U.S. office) supplies systems for production-scale metal additive manufacturing. Modules allow for 3D printing metal parts through selective laser melting and heat treating those same parts within a continuous line, as well as manual unloading via a separate operator module kept isolated from the metal powder. At Formnext, the company showed its latest unit for this system, a Product Removal Module that provides for in-line separation of the parts from their build plate and resurfacing of the same plate. The mechanism of these operations is machining, and the module is essentially a machine tool tailored to automated production AM.

The module works this way:

The build plate, after finishing both the 3D printing and heat-treat operations, is moved into the Product Removal Module. Parts are initially facing up; the module’s first step is to invert the plate, so the parts are underneath, suspended from it. With the parts in this orientation, the unit meets them with its one simple piece of custom tooling: packing foam with pockets cut out to match the parts. This foam carrier is elevated to cradle the parts in anticipation of their fall.

Once the parts are held in this way, a band saw passes between the parts and the plate to cut them free.

The parts at this point are separate and ready to be removed. The build plate, however, is still usable.

The module therefore inverts the plate again so that its used surface can face up toward the other operation. A milling spindle descends from above to follow a CNC milling cycle to machine away the remainder of the previous build’s support structures and machine the build plate flat. The module's work is then complete, and the result is not just parts separated from the plate but also a plate that is ready for another build.

Related Content

-

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

-

Bauer Hockey Uses EOS 3D Printed Digital Foam for Customizing Helmets

The new in-store experience, combined with proprietary 3D printing technology, opens the door for personalized hockey products.

-

8 Ways the Plastics Industry Is Using 3D Printing

Plastics processors are finding applications for 3D printing around the plant and across the supply chain. Here are 8 examples.