Practicality & Possibility

Some of the technologies and applications on display at Euromold 2013 illustrated the possibilities for using additive manufacturing to manufacture functional parts.

The possibilities for additive manufacturing have been growing at a fast pace and, according to one technology player, the industry is now focused on “bringing the buzz down to practicality.” The Euromold trade fair in Germany last December offered an array of unique and exciting AM displays, but the real story was the actual technologies and applications for the manufacture of functional parts, including end-use components and industrial tooling. Here is a sampling of what we saw at this show.

Functional Components from Plastic Droplets

The essential aspect of the machine and part pictured here is that it is possible to produce one-off plastic parts and small-volume batches from 3D CAD files using standard granulate and without requiring a mold. Arburg’s AKF plastic freeforming process produces functional components directly from plastic droplets. This flexible part is an example of a two-component application using a combination of hard and soft materials—polyamide (PA) and thermoplastic elastomers (TPE).

The part was produced without using support structures. It was made from conventional, low-cost standard granulates instead of resins, powders, strips or otherwise pre-assembled materials. The produced part is not a prototype, but a fully functional, high-quality component.

In the AKF process, the machine is filled with the standard plastic granulate, a heated plasticizing cylinder melts the plastic in the discharge unit, a nozzle closure uses fast opening and closing movements to produce the plastic droplets under pressure, and the part is additively built up.

Molds and Cores Built in Days without Tooling

This photo shows a diesel engine cylinder head, along with part of the sand mold and some of the sand cores that were required to cast it. This sand mold and the cores were created using a 3D printing process developed by Voxeljet.

According to Tom Mueller, principal of Thomas J. Mueller and Associates, casting such a cylinder head requires several tools, including patterns for the cope and drag (the top and bottom parts of the sand mold), and a number of core boxes (molds used to create sand cores that will form undercut features in the head). This process can take thousands of dollars and several weeks to complete. Castings with complex flow situations, like cylinder heads and pumps, often can only be optimized by an iterative design-build-test-redesign process, he says. However, the cost and time required to create the tooling for each design iteration makes the process very costly and time consuming.

With the Voxeljet process, molds and cores can be built without tooling in a few days, making this iterative process more cost- and time-effective. In fact, a designer can now simultaneously evaluate several design alternatives to further cut the time required to optimize the design, Mueller says.

Cost-Effective Casting

ExOne’s largest additive manufacturing machines print parts in sand for use in metal casting. Making casting mold components directly in sand, without any need for a pattern or core box, enables not only more cost-effective casting as the caption above describes, but also casting of complex geometries that would not have been practical or even possible with conventional casting molds. The sand-printed part here is an example of an intricate, core-like component that was easy to produce through 3D printing.

Material Savings

A new SLS platform from 3D Systems was used to produce the pump part shown here without tooling. This process is designed to generate a lot of parts fast while producing only about 20 percent material waste.

Of note is the pump’s complex shape, which would typically require long lead times if tooling were needed, but no tooling was required. This part is strong enough to use directly in the field on a machine or an engine, according to the company.

The ProX 500 3D printer used to produce this part builds on the company’s patented SLS technology and, together with its newly developed DuraForm ProX materials, can deliver end-use-ready thermoplastic parts more quickly and more accurately

than previous 3D printers.

Machining Hidden Features

DMG Mori’s Lasertech 65 hybrid solution can do rough machining, deposition and finishing on one machine, allowing a part such as the one pictured here to be built and machined with five axes. The additive features grown off of the central OD show the machine’s ability to reorient the part to build in different directions within the cycle. The drilled holes and milled mating surfaces were created using the machine’s conventional machining capability.

Parts such as this can be built as much as 20 times faster than with powder bed solutions, DMG Mori says. Parts can also be built up in sections, with milling operations used on important areas in between. Support structures are not necessary, and wall thickness can range from 0.5 to 5 mm (0.020 to 0.2 inch).

Dr. Greg Hyatt, DMG Mori’s chief technology officer, explains that an advantage of this process is that it can be used to build up a number of layers, of the same or various alloys, which can then be machined to the required accuracy before the next layers are added. These part areas would not normally be accessible for milling cutters, meaning hidden features can now be machined.

Digital Molding Factory

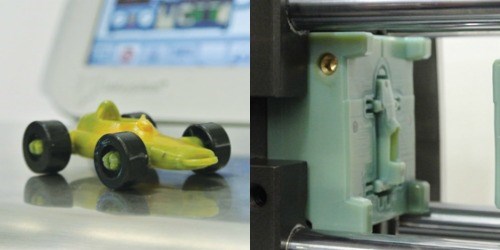

A digital molding system from Stratasys closes the gap between rapid prototyping and aluminum/steel tooling. It gives engineers the option to perform required regulatory and safety tests on the actual product earlier in the process, validating the design and moving forward to production.

Approximately 60 toy race cars like the one shown above were made by injecting

polypropylene (PP) into the small mold pictured here, which was printed from digital ABS material in an Objet Connex260 printer. This run provided a sense of the design, including the snap fits that connect the car body to the wheels, which were formed in a separate mold. Printing the mold for the car body took about six hours, and it cost less than $1,000.

High-Density, Non-Porous, Chemically Pure Metal Parts

Direct metal sintering (DMS) technology allows the accurate, direct printing of high-density, non-porous, chemically pure metal parts (such as this one printed by 3D Systems), yielding high repeatability, reliability and quality.

Metal end-use parts and tooling inserts can be directly and quickly created via this process, cutting out intermediate and time-consuming steps required in traditional manufacturing. This includes complex parts and shapes that would be nearly impossible to produce using traditional methods. In addition, direct-metal-sintered tooling can be used in the production process within a day or two after manufacture, rather than after waiting weeks for the tooling to be machined.

A selection of materials can be used in DMS systems, including stainless steel, tool steel, super alloys, non-ferrous alloys, precious metals and alumina used in the aerospace, automotive and medical device industries.

Two Separate Functional Parts, One Design

An oil separator and cooler that traditionally function as two separate parts were produced as three components in a direct metal laser sintering (DMLS) platform from EOS, then welded into a single part measuring 450 × 260 × 180 mm (17.7 × 10.3 × 7.1 inches). This was later reproduced in one piece, as a concept design, using the company’s new EOSINT M 400 modular, extendable DMLS system above.

This part was built from EOS’s Aluminum AlSi10Mg alloy for a Rennteam Uni Stuttgart racing car. The upper section of the oil separator/cooler uses centrifugal force to deposit oil from air (its rough surface enhances this effect), and the lower portion serves as the oil tank, offering maximized surface area for cooling. The original part was used in a formula-student racing car and proved to have great performance characteristics, EOS says.

With a build chamber measuring 400 × 400 × 400 mm (15.8 × 15.8 × 15.8 inches), the EOS M 400 enables the automated manufacture of high-quality large metal parts. The system consists of a setup station separate from the build area with an automated system in between that clears loose powder from completed parts.

Use of DMLS is said to have contributed to a reduction in the oil separator’s size and weight. A highlight of the new system is that it separates job preparation and calculation from the building process, enabling the job file to be prepared at the designer’s desk and then transmitted via a network to the machine. In this way, the machine focuses solely on building the parts.

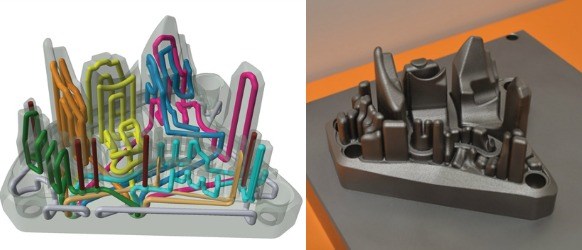

Mold with Eight Complex, Conformal Cooling Channels via Laser Melting

The conformal temperature control arrangement pictured here requires complicated design work—eight outlets of 3 mm (0.12 inch) in diameter and practically identical flow conditions branching out from a 10-mm (0.40-inch) inlet. According to Renishaw and LBC Engineering, this design guarantees uniform, highly turbulent coolant flow and efficient heat transport in each channel. These inserts were laser-generated on

a Renishaw machine with a 0.5-mm (0.02-inch) margin per wall. Conventionally made inserts cannot usually be pre-worked in such detail before hardening, so this means reduced hardening work for cost savings that partly offsets the cost of the laser melting process.

LMD Toughens Automotive Dies

Laser metal deposition (LMD) can increase automotive die life and reduce setup times. That is what researchers at the Fraunhofer Institute for Production Technology IPT, toolmaker Mühlhoff Um-formtechnik GmbH and other Green Carbody Technologies Innovation Alliance (InnoCaT) partners set out to prove during Euromold with their new universal, reproducible, industrial-use LMD process.

During LMD, a laser beam carefully melts the surface of the die and the filler material to produce a local layer that guards against wear on the die surface. This treatment, which is completed in fractions of a second, is designed to increase the robustness and resilience of the stainless steel die at critical points.

The group rebuilt a conventional five-axis milling machine (pictured here)—which can be installed within the current manufacturing process—for the automated LMD of forming dies. According to Fraunhofer, this processes increases the lifetime of dies by more than 150 percent, improves the quality of components and makes it possible to plan setup times with greater precision.

Another key part of the LMD system is integrated software that enables the laser surface treatment processes to be controlled in a clear, reproducible way. All necessary process parameters are transmitted to the machine without the need for any interface. Processes can be simulated in detail and optimized in advance of actual processing operations.

Read Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More