When I first spoke with MolyWorks founder Chris Eonta in early 2020, the company was at an inflection point — yet not the one we’ve all come to associate with that year. MolyWorks was at the moment of pivoting its R&D work on additive manufacturing powders made from recycled metal scrap into a production-focused business. “It’s hard to say whether coronavirus had any impact on where we are now,” Eonta says, because so much was changing all at once.

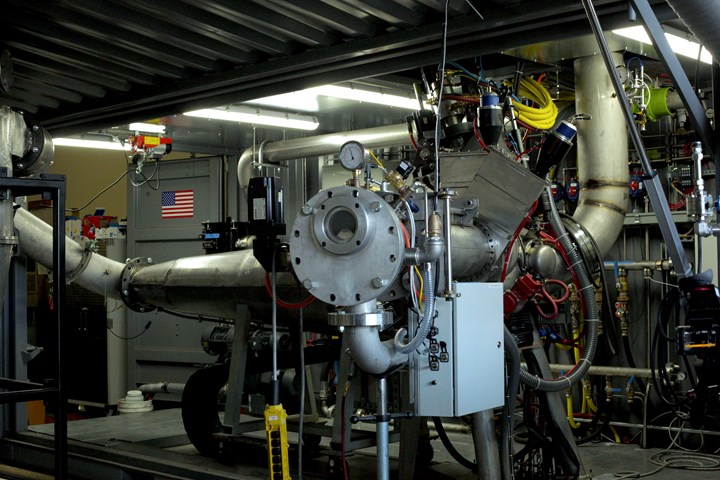

Two years later, MolyWorks has evolved into a powder-production company using the technology its founders first developed inside a backyard shipping container. The unit now has a catchier name (the Greyhound), but its small footprint hasn’t changed; the system still melts, refines and atomizes metals into powders suitable for AM within a 20-foot-long container. Alongside powder production the company is also developing printer parameters for exotic alloys and printing parts for customers, leveraging a recently earned ISO certification. And, it is preparing to ship a second, sleeker Greyhound unit to Singapore to produce metal powders for the additive manufacturing market in Asia.

Inside the Greyhound that is destined for Singapore. The self-contained unit housed inside a shipping container can melt, refine and atomize metal scrap and other feedstock into AM-grade powders. Photo Credit: MolyWorks

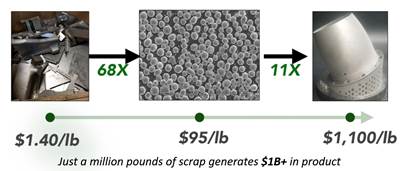

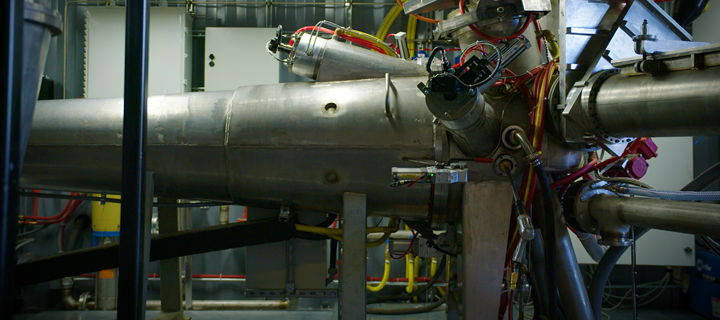

The company’s goal is to create a sustainable, circular loop for metals, by using scrap and discarded parts as the feedstock to make new powders for additive manufacturing. The Greyhound uses a 240-kW plasma torch to melt scrap metal, which then falls through a horizontal stream of argon gas to be spheroidized into powder particles. The powder drops into a small, custom designed hopper for transport to the sieving station, and from there can go on to be used in additive manufacturing. The system can process about 50 to 100 kg of material an hour and can be recharged continuously without opening the system to air, Eonta says.

A 240-kW plasma torch inside the reactor melts the feedstock so that it can be atomized. Photo Credit: MolyWorks

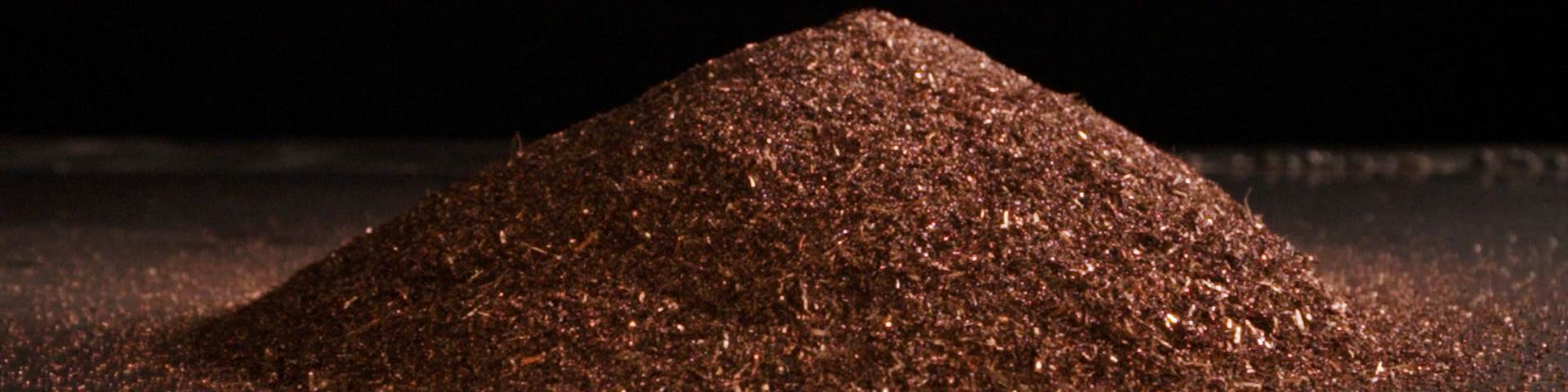

The throughput is important, because for the moment powder production is the company’s main activity. In fact MolyWorks’ current bottleneck is not atomization but the sieving step necessary to process all the material the Greyhounds are making. MolyWorks produces mainly exotic and novel alloys for customers, using scrap material as the feedstock wherever possible. Materials routinely produced include beta titanium (used in landing gear), 4340 steel, nickel 718 and 316L stainless steel, as well as novel alloys developed for NASA and military clients. Developing new materials for the Greyhound typically involves developing the “recipe” for atomization, and then moving to a laser powder bed fusion printer to develop the print parameters as well before passing the material to the customer.

After sieving, the atomized powder is ready for use in 3D printing. MolyWorks commonly processes alloys including Ti64, 4340 steel, nickel 718 and 316L stainless steel. Photo Credit: MolyWorks

In some regard the vision for a circular economy with metals is already playing out. For certain customers MolyWorks is currently producing metal AM powders using the client’s own scrap, returning the high-value material to them with a zero-waste certificate validating its circular nature. Ultimately, though, the future MolyWorks is looking toward is one where the customer would have a Greyhound on site and convert their own scrap to powder locally, right near where manufacturing takes place.

The new unit bound for Singapore reflects a number of upgrades and lessons learned from the original one which will make it easier for MolyWorks to operate at its destination, but also easier for a different potential user in the future. The control station, for instance, has been simplified from four monitors down to two and made more user-friendly. The compressor inside the atomizer was upgraded for better control over the gas flow, a critical parameter for producing good powder. An automated feeder with gate valves preserves the heat and vacuum inside the unit, allowing for refilling the feedstock material without stopping the atomizer.

The Singapore unit is the second generation Greyhound and includes upgrades based on lessons learned. Photo Credit: MolyWorks

But through all these upgrades, the Greyhound has retained its compact size. A shipping container offers a convenient housing for the system, something that could be right at home on a military base or at an OEM’s factory. As additive manufacturing adoption advances and volumes increase, MolyWorks expects that the solution will find its place at facilities doing production additive manufacturing alongside machining or other scrap-generating processes.

“If you have a lot of scrap, you’re just like any other manufacturing facility,” Eonta says. “This is a solution for companies that have a lot of scrap generation, and are doing a lot of additive manufacturing. The industry is getting to the point that it’s ready.”

Related Content

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreRead Next

Rounding Out the Circular Economy With Material Take-Back Programs: AM Radio #6A

One of the most difficult steps in the circular economy is going from product back to new material. On this episode of AM Radio, Julia Hider and Stephanie Hendrixson discuss how material take-back programs can help solve this challenge.

Read MoreIs Recycled Metal Scrap the Future Feedstock of Choice for Metal 3D Printing?

MolyWorks is future-proofing the circular economy for metals with small-footprint atomization technology that converts metal scrap into additive manufacturing powder on the spot. But that's not the end of the story.

Read MoreGetting to a Circular Model for Metal Powders Makes AM More Sustainable

6K’s UniMelt process offers efficiency and control in the production of metal powders for additive manufacturing. But more than that, it is a home for unused and oversized powder, metal scrap and more that can close the loop on metals.

Read More

.jpg;width=70;height=70;mode=crop)