Is Direct-Digital Manufacturing Right For You?

Additive fabrication technology has moved beyond prototyping. These four indicators can help manufacturers decide whether to consider direct-digital manufacturing (DDM) for their operations.

Additive manufacturing processes such as stereolithography have become popular for rapid prototyping of new product designs. That said, additive fabrication has moved beyond simply proving out designs, says Joe Hiemenz, public relations manager for Stratasys (Eden Prairie, Minnesota).

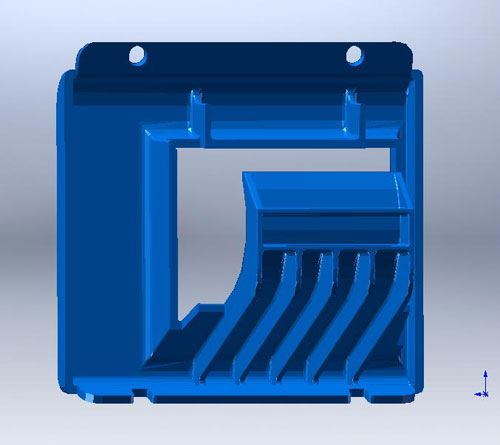

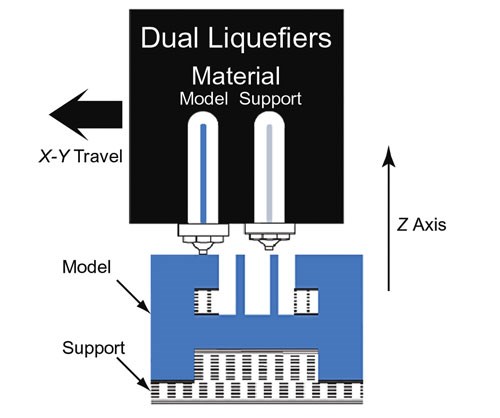

Recent developments in these manufacturing techniques have led to the advent of direct-digital manufacturing (DDM), in which an additive process constructs end-use parts. According to Hiemenz, this trend is especially evident in manufacturing jigs, fixtures and other tools used in production and assembly processes. It is also being used to create custom components as well as medical and dental parts. He says that’s because DDM processes such as fused-deposition modeling (FDM), developed by Stratasys, can be faster, more affordable alternatives to manufacturing such parts via machining or injection molding. The FDM process melts solid plastic and extrudes it through nozzles about as thick as a human hair (approximately 0.005 inch). Those nozzles lay fine beads of molten plastic layer-by-layer to quickly build parts directly from a 3D CAD model.

But how do you know if FDM or another additive manufacturing process is right for you? Heimenz suggests targeting applications that have one or more of these four attributes.

Low Production Volume

DDM is most appropriate for parts produced in quantities of less than 3,000 per year. This is one reason that DDM is increasingly used in applications for jigs, fixtures and other tools used in the assembly process. For example, a large automotive manufacturer may produce hundreds of custom tools but need only 30 to 40 of each design. DDM can help such manufacturers avoid the high costs and lengthy waiting times involved in traditional methods such as machining injection molds or in bidding out that work. Small manufacturers producing components in low volumes can benefit in similar ways.

High Design Complexity

Although DDM can be used to produce simple objects, the cost and time advantages are more pronounced when parts have complex shapes, intricate designs or numerous features. Additive processes such as FDM are insensitive to design complexity. Building material up layer-by-layer to complete the part eliminates problems such as creating internal cavities and complicated 3D contours. It also doesn’t require the workpiece to be set up or refixtured multiple times. However, parts requiring very tight tolerances (greater than ±0.005 inch) may require additional finishing work.

High Probability Of Change

Design changes can be expensive and time-consuming when using traditional subtractive manufacturing processes. On the other hand, DDM allows freedom to redesign at will. Manufacturing a revised design is simply a matter of modifying the CAD data, exporting a new programming file and starting the machine. There is no additional cost for rework or retooling, and there is no interruption in production schedules. In this way, DDM serves as a bridge to production—it provides flexibility to change a product’s design after its launch. This also explains why manufacturers of custom products, such as those in the medical and dental fields, have been early adopters of DDM.

High Startup Investment

All subtractive manufacturing processes involve substantial investment of labor, time and money for toolpath creation, fixtures, molds and machinery. For example, a single injection mold can cost $75,000 or more and take anywhere from 8 to 16 weeks to manufacture. FDM has no tooling costs, and the waiting period for the first production parts may amount to only a few hours or a few days at most. This not only minimizes new-product startup investment, but can translate to better cash flow, improved profit and decreased debt for a company. Lowering the initial investment also opens the door to more product introductions.

Heimenz says that while manufacturers using traditional machining and/or fabricating techniques can make parts from virtually any plastic, DDM processes are somewhat limited in this area. Additive technologies such as FDM and stereolithography, for example, can use only certain formulations of plastic, so they may not be useful for parts that require certain thermal or strength properties. However, if your application is open to being converted to select plastics, additive processes such as FDM are worth considering.

Related Content

PowderCleanse Concept Delivers In Situ Powder Analysis for Metal 3D Printing

A collaborative project developed a prototype solution for measuring particle size distribution on the production floor, as part of the sieving step typical to additive manufacturing processes using metal powders.

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreAdditive Manufacturing's Evolving Role at Fathom Now Emphasizing Bridge Production

Bridge production is currently the biggest opportunity for additive manufacturing, says Fathom Manufacturing co-founder Rich Stump. How this service provider leverages AM while finding balance with other production capabilities.

Read MoreHow Avid Product Development Creates Efficiencies in High-Mix, Low-Volume Additive Manufacturing

Contract manufacturer Avid Product Development (a Lubrizol company) has developed strategies to streamline part production through 3D printing so its engineering team can focus on development, design, assembly and other services.

Read MoreRead Next

The Manufacturing Network as a Source for Internal Custom Tooling

For a tool that includes both machined and 3D-printed components, all the pieces of the tool can be made by separate companies yet arrive together. BMW has used Xometry to obtain tooling in this way.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More