GKN and Porsche Develop AM Transmission Part Using New Metal Powder

Using a combination of metal powder-bed fusion and metal powder 20MnCr5, GKN Powder Metallurgy and Porsche 3D-printed an intricate differential housing with gear ring unit on a front traverse transmission.

Today’s automotive manufacturers are faced with the ever-increasing demand of improving vehicle efficiency. Manufacturers have tackled the problem from all angles: reducing weight, creating more efficient internal combustion engines, improving powertrains, and reducing noise. But to achieve a more efficient vehicle, the automotive market has started using metal additive manufacturing (AM)

Metal AM enables the development of innovative solutions and shortens time-to-market duration. AM is used for prototyping parts and to mass manufacture parts that require a unique shape, typically impossible to achieve via traditional machining. For automotive, the development of more efficient powertrains, combined with AM design freedom, enables the creation of functional-integrated and weight-reduced AM steel grades that still withstand high wear and loads.

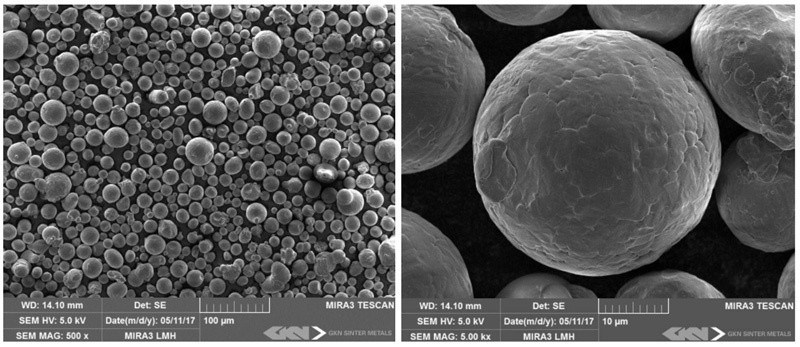

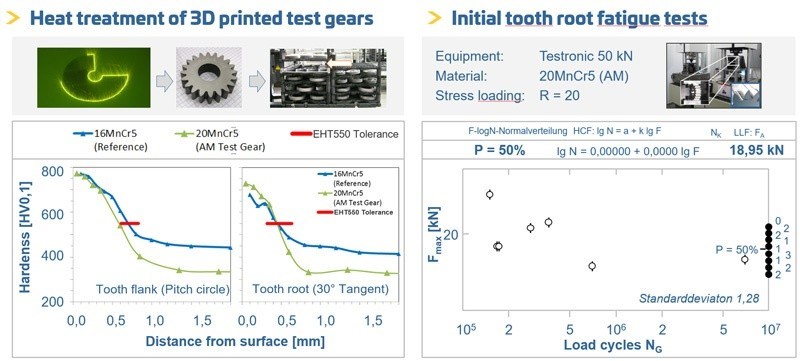

GKN Powder Metallurgy has developed a powder material designed to fit the requirements of the automotive industry: 20MnCr5. This steel grade powder is said to offer ductility without compromising strength, wear resistance through case hardening, high fatigue strength and toughness that doesn’t detract from machinability. This material can form a medium-strength steel grade able to be case-hardened and which has high wear resistance, mechanical strength and performance-to-cost ratio, the company says. Furthermore, initial test results indicate that 20MnCr5 can meet current 16MnCr5 medium steel quality levels.

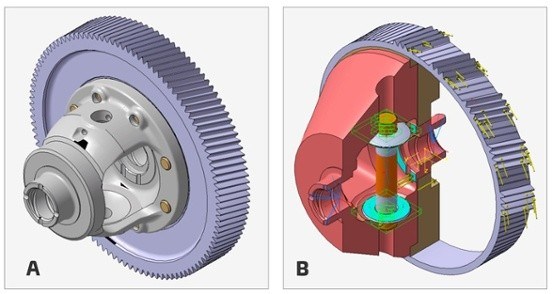

To validate these results, GKN and Porsche used 20MnCr5 to 3D print a conventional front transverse transmission. They chose to design the transmission part with the largest weight reduction potential: the differential housing with ring gear unit. Ultimately, they created a more efficient transmission part that could not have been produced without AM.

Using CAD and topology structural optimization software, GKN and Prosche designed a new shape for the differential housing with ring gear unit. They first defined the maximum available space within the transmission and subtracted the inner contours needed by any function (bevel gears, side shafts, bearings, etc.) from the body of the part (see Figure 4).

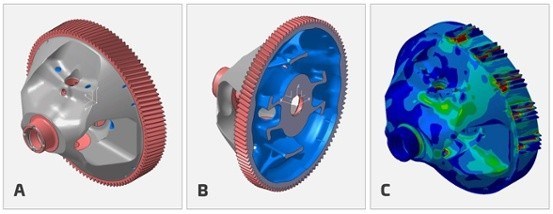

Based on the specifications and requirements of the transmission, all loads (bearing and gear) were applied to the package block. The CAD optimization tool delivered a structure capable of taking all required loads. The resulting structure (Figure 5) is not producible with conventional tools, but creating the product close to the calculated structure is possible with AM. For example, the inner shape of the differential housing part is supported by a system of organic beams and structures that are necessary for its structural integrity. While these shapes cannot be machined with traditional methods, AM enabled the part to be printed from scratch. The AM process does require that the part be designed with special features such as holes to eject the unused metal powder or openings on the outer diameter to drain collected oil, but these features can be designed into the model from the beginning.

The final finite element analysis showed a very homogeneous stress level. This enabled a reduction in wall thickness, a characteristic not previously possible. Based on the original load requirements, the calculation achieved a 13 percent weight reduction, a 43 percent reduction of tooth stiffness variations in radial direction, a 69 percent reduction of tooth stiffness variations in tangential direction and an 8 percent reduction of inertia.

The use of AM with special metals like 20MnCr5 introduces a future of metal additive production that yields parts that are weight efficient and structurally strong.

Adapted from an article that originally appeared on GKN’s blog.

Related Content

Daimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreFaster Iteration, Flexible Production: How This Inflation System OEM Wins With 3D Printing

Haltec Corp., a manufacturer of tire valves and inflation systems, finds utility in 3D printing for rapid prototyping and production of components for its modular and customizable products.

Read More8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More