Bespoke Laser Cladding Nozzles Made Possible with Powder Bed Fusion

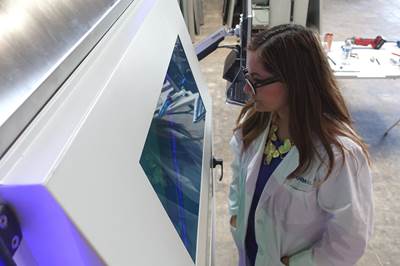

Additive manufacturing is advancing laser cladding. With the addition of a powder bed fusion 3D printer, American Cladding Technologies can now print custom cladding nozzles to meet the precise requirements of each job.

American Cladding Technologies applies laser cladding to repair and production of parts for the oilfield, aerospace and power generation industries. Custom cladding nozzles, which can now be made via powder bed fusion, allow it to take on challenging applications such as cladding of interior surfaces. Photos: American Cladding Technologies

American Cladding Technologies (ACT) specializes in powder-based laser cladding, a directed energy deposition (DED) process that applies powdered metal to cover an existing surface or features. But ACT doesn’t handle just any metal cladding application — instead, the company tends to get the work that is tricky, challenging and often has been attempted unsuccessfully by others, says Chris Proulx, vice president of sales and marketing.

As such, ACT is constantly modifying its tools and technology to suit each application. “We’ve never been ‘plug and play.’ We’re always customizing our tooling,” Proulx says. “We’ve purchased nozzles and machined them to suit our needs. We’ve also built our own nozzles for applications that had difficult geometries or needed a certain clearance.”

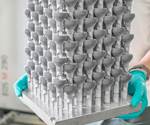

ACT recently added a different form of metal-powder-based technology, powder bed fusion (PBF) metal 3D printing, to expand its portfolio of manufacturing services. In the PBF process, loose powder is contained in a build envelope and melted point by point with a laser. At ACT, this capability is being used to make production parts for customers, but is also serving another, internal purpose: building custom nozzles to improve the efficiency, performance and cost of its laser cladding operations.

Applying Metal Cladding for Repair and Beyond

American Cladding Technologies is the laser cladding arm of Joining Industries, a collection of business operations located in East Granby, Connecticut. Sister divisions are Joining Technologies, which focus on laser and electron beam welding primarily for medical devices plus military and aerospace applications, and Joining Technologies Automation, which designs and builds laser-based manufacturing cells. ACT was formed about four years ago to focus exclusively on metal cladding. In late 2017 the division moved into a separate facility for more space.

The company serves industries including power generation, petrochemical and aerospace, and recently earned its FAA repair NADCAP certification (on top of existing ASME and AS9100 qualifications). ACT is equipped to handle parts ranging from small valves to boiler tubes measuring as large as 40 feet in diameter. “Anything that is subject to wear, corrosion or erosion,” is how Proulx summarizes the company’s focus. About 80% of ACT’s work is in repairs, which means laser cladding material onto existing workpieces; only about 20% is new products. An in-house metallurgy lab develops alloys and evaluates each application to determine whether a part can be suitably clad with its process.

For inner diameter (ID) cladding, which has been ACT’s focus for the past 8 months or so, custom nozzles have proven especially important; metal cladding the insides of plastic extruders, oil drill bits, pipes and similar parts requires nozzles that can meet the length and area requirements of the application. Previously, this meant working with the tool and machine shop at Joining Technologies to create a nozzle from scratch or modify an existing one. The time from design to completed nozzle could be as long as two months, Proulx says. 3D printing these nozzles offers a much faster route to customization.

ACT’s powder bed fusion lab was established in 2019 with the purchase of its Trumpf TruPrint 3000 system.

Powder Bed Fusion AM Improves Laser Cladding

When ACT was asked to take on an aerospace production job that required powder bed fusion at the end of 2019, it was an easy decision to install a Trumpf TruPrint 3000 metal 3D printer. With its history in welding, Joining Industries has a longstanding relationship with the builder, which supplies welding and machining equipment in addition to metal 3D printers.

ACT is using its PBF metal 3D printing capacity to manufacture its own cladding nozzles, as well as production parts like these aerospace components.

That original production job was put on pause because of the coronavirus, but the 3D printer has not sat idle. When I spoke with Proulx about 5 months after its installation, ACT had already explored no less than 15 different applications for various customers in Inconel and 316 stainless steel in addition to applying the PBF capability to its own internal nozzle needs.

“We are now able to design and 3D print our own laser cladding nozzles with features that simply weren’t possible with conventional machining,” says Jeff Whittaker, ACT president.

Each nozzle is proprietary and designed to suit a particular application (and thus not pictured in this article), but Whittaker summarizes a few of the improvements that PBF has made possible. The 3D printed nozzles enable better shielding gas coverage, reducing the oxygen in the melt pool and improving metallurgy; stabilized laser spot sizes and geometry for a more consistent process; internal channels to improve cooling during high-heat applications; and increased powder efficiency, which translates to reduced cost to the customer.

Importantly, these complex and more capable 3D printed nozzles do not add additional lead time to the manufacturing process; in fact, just the opposite. Where a custom nozzle might have taken 2 months to develop and machine from scratch, a 3D printed one can be rapidly iterated and produced now in just a matter of days. “We can now speed through that process,” Proulx says. “With 3D printing, it’s more efficient, streamlined and flexible.”

Related Content

Two 12-Laser AM Machines at Collins Aerospace: Here Is How They Are Being Used

With this additive manufacturing capacity, one room of the Collins Iowa facility performs the work previously requiring a supply chain. Production yield will nearly double, and lead times will be more than 80% shorter.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MorePreassembled Turbojet Engine, 3D Printed in One Build: The Cool Parts Show #75

Turbojet engines typically consist of hundreds or thousands of parts, but this engine — 2023 winner of The Cool Parts Showcase for Best Proof of Concept — was 3D printed as just two pieces, with the monolithic rotor embedded inside the stationary engine shell.

Read More3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

Read MoreRead Next

Directing the Future of Laser Metal Deposition (LMD)

Formalloy is proving that LMD is for more than repairs and large parts. Fast deposition rates, fine detail capabilities and multimaterial support promise to change how parts are designed and made.

Read MoreAM Is Advancing into Tools for Machining: Examples from EMO

The design freedom of additive manufacturing delivers increased performance to tools used in subtractive processes. At the world’s leading exposition for machine tools, I saw various examples of this.

Read MorePushing Laser Powder Bed Fusion into New Realms of Productivity

The Betatype technology stack supports businesses looking to expand on the potential of additive manufacturing for series production through design-led thinking and unique optimization algorithms to maximize the capacity of LPBF systems.

Read More

.jpg;width=70;height=70;mode=crop)