Additive Manufacturing versus COVID-19: Protecting Your Ideas for Protecting Others

Reporting from the front lines of the fight against Coronavirus – battling liability and IP issues.

A functioning stethoscope made with 3D printed parts, brake cables, and aquarium tubing. Photo credit: Penn State MASC Initiative

We’ve seen it happen before. Someone shares a 3D solid model of a cool design only to find that someone else has downloaded it, 3D printed it, and is selling it on an e-commerce site. How would you respond if this happened to you? When it happened to Thingiverse designer Louise Driggers, she responded by posting a 3D model of a sad face, resulting in over 900 comments and dozens of others realizing similar things had happened to them. Meanwhile, Thingiverse changed their file downloading process to ensure that relevant licensing information from Creative Commons or any other open source license is prominently displayed during the download.

It should come as no surprise, then, that this persists in the Age of COVID-19. Prusa was among the first to share its 3D printed face shield design for free on their website, and they did so under a non-commercial license. They asked that the shields be donated (for free) to those that needed them but they also allowed for the producer to cover manufacturing costs; however, they “do not want to see these shields on eBay for $50.” Well, guess where they are now? Selling on eBay and other e-commerce sites for as little as $3 and as high as $17. Granted, it isn’t $50, but still, it is definitely more than the cost of materials required to make one.

As you might imagine, Prusa’s face shield isn’t the only one suffering this fate. You can find all sorts of 3D printed PPE (Personal Protective Equipment) on eBay and other e-commerce sites right now given the scarcity of PPE in the traditional supply chain. Some of the PPE even boasts “NIH Approved” because it was downloaded from the NIH 3D Print Exchange. Now, is NIH going to pursue any of these sellers and prosecute them for downloading and trying to make a buck off of their hard work? Well, it depends on the license associated with the file that is downloaded. Creative Commons licenses, for instance, come in six variations depending on how the originator allows the work to be used, remixed, and distributed (either commercially or non-commercially) as long as the originator is credited. If the work exists in the public domain like the JPL Performance Respirator, then anyone can take it, remix it, and even sell it without permission or attribution.

So while it may seem unethical, in some cases it is permissible to take someone’s design, 3D print it, and sell it on an e-commerce site. The new wrinkle in the Age of COVID-19, however, deals with product liability — who is liable if someone gets injured or contracts COVID-19 while wearing 3D printed PPE? Well if you bought it on eBay, for instance, eBay is not liable for the products sold on its website thanks to Section 230 of the Communications Decency Act. So is it the seller who is liable or will the seller blame the party who created and shared the 3D CAD model — or cast the blame on NIH for hosting it on their 3D Print Exchange?

Unfortunately, the answer is not straightforward when it comes to product liability for 3D printing someone else’s CAD model or STL file. A CAD or STL file is a file, not a physical product, and if it is freely available for download, then there is no economic loss associated with its failure to perform. If the CAD or STL file is 3D printed and the user is harmed while wearing it, for instance, 3D printed PPE that fails to protect users who then contract COVID-19, then it becomes a real legal issue, and the originator of the CAD (or STL) file better make sure that s/he is protected. This gets into warnings and issues of indemnity (i.e., compensation paid by one party to another for any loss, damages, or liability that is incurred), and it has been interesting seeing how different 3D printing companies and repositories are handling this when it comes to PPE. EnvisionTEC, for instance, simply asks that you to read, acknowledge, and agree to the terms and conditions in their release waiver before downloading and 3D printing any of their files. HP used a similar approach initially, but now they require you to check a box to agree to HP’s terms and conditions before you can download files for 3D printing. Carbon, on the other hand, requires you to submit your contact information or be a registered user with Carbon Academy before they will share any files related to COVID-19.

So why am I telling you all this? Well, being on the front lines for the past two months helping fight COVID-19, product liability, indemnification, waivers and release forms, and intellectual property (IP) have all come into play as we have scrambled to help healthcare workers address critical supply chain shortages. While PPE is high on that list, single-use stethoscopes became an issue two weeks ago as our inventory was about to run out. Supply became limited, orders faced a two-month backlog, and prices increased from $1.25/stethoscope to nearly $6.00 each.

In search for an alternative solution, our team found the free/open source 3D printed stethoscope developed and validated by Dr. Tarek Loubani and his team in 2018. We downloaded and 3D printed the files posted on GitHub, sourced the rest of the components at a hardware store, and assembled a working stethoscope within a day (see figure). It was pretty amazing to find a 3D printed solution so quickly, but we realized that we were now clearly making medical devices, not just PPE. The acoustic quality was great, but what if a patient was incorrectly diagnosed using our 3D printed stethoscope? Moreover, we certainly were not making it within a cGMP-compliant facility, and we had not registered it with the FDA (it is a Class 1 medical device); so, what was our liability? We weren’t violating anyone’s IP, and we weren’t selling the product commercially, but we were certainly exposing ourselves and the doctors to significant risks that we had not considered when 3D printing PPE.

Needless to say, we are not manufacturing 3D printed stethoscopes for use; instead, we continue to refine the design based on feedback from the doctors that test our prototypes. Meanwhile, we are talking to cGMP-compliant manufacturers that are registered with the FDA to see if any of them want to manufacture 3D printed stethoscopes, but now it is a business decision that depends on supply and demand — the cost to manufacture it versus the selling price — which changes daily thanks to the rise (or fall) of Coronavirus cases.

Open source and 3D printing are great when flexibility and agility are important, but when people’s lives are at stake, make sure that you and your IP are properly protected as you help protect them.

Related Content

3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreSpherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.

Read MoreRead Next

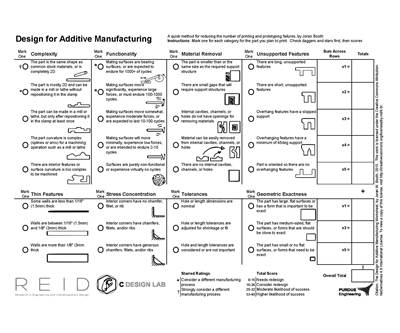

How a Worksheet Can Elevate AM Success

How a simple worksheet can help improve success with additive manufacturing.

Read MoreLeader of New Jersey PPE 3D Printing Effort Tells Volunteers, “Stop Completely”

“PPE Made in the USA” delivers 5,000 3D printed face shields produced and distributed by 50 volunteers. As emergency passes, a high school STEM teacher’s response to the COVID-19 crisis reaches its conclusion.

Read MorePPE Shortage Catapults Human Solutions Tech into Production

The organization was intended to solve unmet needs in the local community. Its founder didn't anticipate that its first project would be face shields.

Read More