They accelerate from 0 to 190 mph in 10 seconds, fly around corners at such speeds that the driver experiences G force close to that of an Apollo astronaut during Earth re-entry, and then decelerate from 62 to 0 mph in about 48 feet.

Formula One racing cars are a true feat of automotive engineering. The people working behind the scenes of what we see on a race Sunday are regularly achieving small miracles of aerodynamic, design, manufacturing and materials science, things that can be masked by the final race results.

While it is usually the bigger teams who secure the best spots on the podium every year, all ten teams are constantly pushing the boundaries of science, engineering and design, including the Alfa Romeo Sauber F1 Team and Sauber Motorsport AG. Founded by Peter Sauber, the Swiss team entered Formula One in 1993 and launched the careers of some of motorsport’s most famous names including Michael Schumacher, Kimi Raikkönen and Sebastian Vettel, who made his grand prix debut driving for Sauber and is known for setting fastest times during Friday practice appearances in 2006.

But even the best drivers cannot take the checkered flag without the best-possible engineered race car. The general shape of a Formula One car is defined by the technical regulations of the FIA, the governing body of motorsports, but within the rules, engineers design a new car every year that’s not only sleek but more importantly one which must produce massive downforce to keep the car on the track.

To see what’s behind the scenes of the epitome of bleeding-edge engineering, I and made my way to the Sauber headquarters in Switzerland.

In-House Manufacturing

The Sauber Group’s extensive facility is a modern complex which consists of three sections, totaling more than 15,000 square meters of offices and production space including a closed-circuit wind tunnel reaching wind speeds of up to 300 kph.

The thing that surprised me most about the company’s operations in Hinwil near Zürich is the high level of vertical integration and the number of in-house, custom-built parts made of carbon fiber, plastics and metals including aluminum, titanium and magnesium alloys. Since Formula One teams are only allowed to build and run two race cars per season (plus a third car disassembled in spare parts) and FIA regulations are very tight, a layperson in Formula One like me wouldn't have expected to find a manufacturing facility of such a large scale where about 80,000 parts are built per year, including 5,000 3D-printed parts per month.

The Alfa Romeo Sauber F1 Team is obviously no stranger to the advantages of additive manufacturing (AM) to produce custom tooling, prototypes, test parts or end-use parts. Six SLS and six SLA machines have been running in-house since 2007, and as of last year are complemented by metal AM systems.

After extensive research, the team decided to install two industrial-grade production systems from Additive Industries in 2017. The Netherlands-based company’s MetalFab1 machines are based on powder-bed fusion technology and are targeted to meet the demands of industries where serial parts have to be produced with a high degree of repeatability and process control. In addition to the core 3D printing process, heat treatment, automated build plate handling and storage are integrated into the machine.

But does an F1 team really build enough parts to justify production-scale machines? Don't F1 teams "just" need parts to run two cars per season? Well, it's not that simple; in fact, Formula One racing is not a simple business at all.

Speed Is All-Important—In Racing and in Production

"Every season sees a completely new car," says Christoph Hansen, head of additive manufacturing at Sauber Engineering. "Moreover, each track has different requirements. Monaco, with its tight corners, wants as much downforce as possible and grippy tires; Monza, with its long straights, demands minimal drag and hard-wearing tires—and thus cars are almost completely reconfigured and rebuilt between races. Here, AM has helped reduce production lead time by 20-25 percent, cutting down on the machinists’ programming time, and provided a further massive gain on the material supply chain.”

The configuration for each car is mostly derived from thousands of simulations via software and on test rigs. Modified car parts have to be run through computational fluid dynamics (CFD) and put in the wind tunnel before they're manufactured. And wind tunnel usage is also restricted by F1 regulations. For instance, F1 teams are only allowed 25 hours of "wind on" time per week to test new chassis designs; the number of runs, tunnel occupancy and speed is restricted; and only model size at 60 percent scale are allowed in the tunnel.

"As a result, we not only have to build the final parts which are used on the actual race car, we also have to build scale models of the actual car complete with suspension, wings and driver's helmet," he explains. "The model is made of a stiff skeleton on which the various parts made of aluminum, titanium, plastic or carbon fiber are bolted or glued. AM makes it relatively easy to produce components that can be quickly evaluated in the wind tunnel."

“The beauty of AM is of course that we can build numerous variations of angles and shapes for testing before the final component is manufactured...”

Since these components take various race conditions into consideration (depending on the downforce, wind, track conditions, etc.), each part to be aerodynamically tested needs to be manufactured in many different versions. "If I need ten different versions of a part on the front wing, which takes say three days to be conventionally produced on a milling machine, then the time savings to 3D print the different versions in-house definitely outweighs the investment costs of our AM machines," Hansen says.

“We manufacture a large number of aero components for the front wing, in particular, that offer a significantly higher level of wind-tunnel performance,” Hansen explains. “The beauty of AM is of course that we can build numerous variations of angles and shapes for testing before the final component is manufactured in carbon fiber, which is a much longer and more expensive process.” For car production, the company manufactures molds, laminated cores, and trim and bonding jigs.

Out of the roughly 1,000 metal AM parts produced per month (700 made of AlSi10Mg, 300 made of Ti64), which also includes business for third-party customers, the production of aero components for wind tunnel testing accounts for the greatest use of the metal AM systems at Sauber, with a variety of shapes that make the most of the full build volume of the MetalFab1 system, which measures 420 × 420 × 400 mm. (Where necessary, metal AM parts are joined together to enable the manufacture of much larger structures.)

AM Components for Testing and On-Track Use

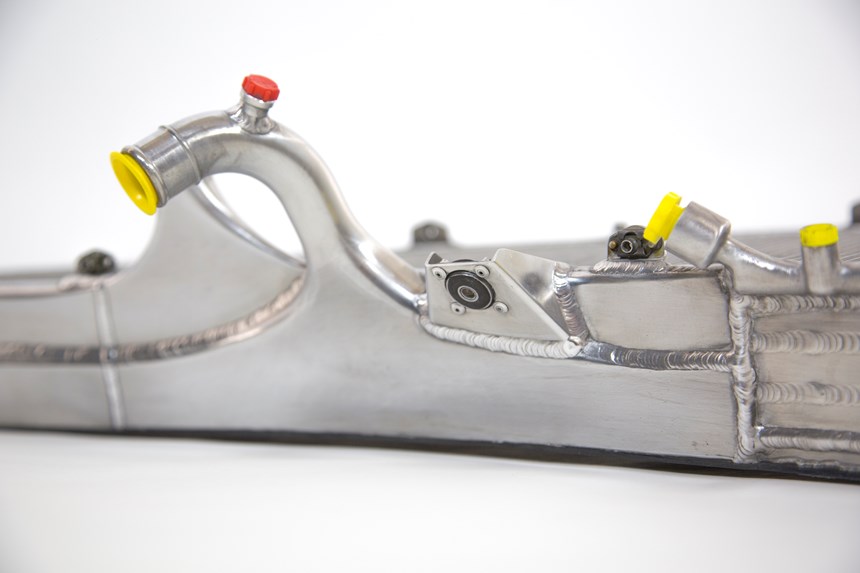

Sauber also produces metal AM components destined for use on the final cars, including upright covers, garage equipment, exhaust components, the Scalmalloy roll hoop, and several unique sets of intercooler and radiator inlets and outlets per car. (As Sauber receives its engines and gearboxes from Ferrari, it has no involvement in the development of metal AM parts for these systems.)

The upright covers are part of the wheel suspension system and need to be made of metal, according to the regulations. “The cover needs to be as thin as possible,” Hansen explains. “To create this particular shape, additive manufacturing is the only way to go today. The cover hasn’t been part of the regulations for the past five years, but it has been before. Back then, it had to be manually beaten and welded, an enormous effort.”

The roll hoop, a critical safety device which protects the driver in case of a rollover, is probably one of the most interesting AM parts on the car. Made of aluminum-magnesium-scandium alloy (Scalmalloy), the device can support 12 tons of force even though it is hollow, supported by complex internal features for structural integrity. The high-strength aluminum alloy has been developed for selective laser melting and exceeds the tensile and fatigue strength of the aluminum alloy used for other parts at Sauber (AlSi10Mg) by as much as 70 percent.

"Every gram counts, so we try to keep the weight of this high-up part as low as possible to bring the center of gravity down towards the lowest point in the car.”

While structural integrity is clearly paramount, the roll hoop can also provide an aerodynamic advantage that can be leveraged. According to Hansen it is important to make the part as light as possible because it is mounted on the highest point of the car. "We try to make the car as light as possible, even less than required or demanded by the regulations," Hansen explains. "Every gram counts, so we try to keep the weight of this high-up part as low as possible to bring the center of gravity down towards the lowest point in the car. If a car is designed too light for the regulations we can include additional weight into the car’s underbody.”

The biggest advantage of using AM for the roll hoop is being able to design the part with more freedom, and not conforming the part to the machinery that produces it. “New shapes which cater to our needs have become manufacturable, and as a result, we have been able to reduce the weight of the component quite considerably,” Hansen says. “Prior to using metal AM for production, we were machining roll hoops from aluminum blocks. Traditionally, the ordering lead time of the big aluminum blocks used as blanks was six months. Furthermore, the blocks themselves were inconsistent in strength due to the nature of the heat treatment that each block received. Because of this, we always needed to order materials in excess and scrutinize each block to make sure the mechanical properties were high enough to guarantee a safe installation on our car. In comparison, the materials required for the additive manufacturing machine are much easier for us to acquire, and always in supply.”

According to Hansen, Sauber has all the technical knowledge and expertise to build the roll hoop in-house and will start production for next season’s car.

AM Systems Need to Run 24/7

For next season, the team will own a third MetalFab1 machine from Additive Industries, featuring four lasers, integrated powder handling, storage, and a heat treatment device.

“For us, the modularity of the Additive Industries system is a big plus,” Hansen explains. “It enables a wider material mix and equates to a much lower investment when, for example, you want to process four different materials. An AM system needs to run 24/7 in order to recoup the necessary investment and if a machine has to be out of service for an extended period for cleaning, then this has a serious impact on our production capacity and schedules.”

Thanks to swappable build modules, or “AM cores,” each machine offers a high level of production flexibility. Sauber Engineering has ordered two AM cores for each machine, meaning that it will have the capability to process four different materials if required without the need to strip and clean the machine. This time savings will enable Sauber to run the machine as much as possible to make parts both for its F1 cars and external customers.

Center of Excellence in AM

"We have been a user of polymer 3D printing technology for over a decade and can now build on this expertise for our metal AM production facilities, not only to produce our own parts, but also for our third- party business,” Hansen says. Services offered by Sauber include concepts, development work, consulting and products in all key technical areas—not just AM—such as wind tunnel tests, CFD, model building, vertical dynamics, tire analysis, kinematics and lightweight construction.

“We help our customers to learn how to ‘think additive,’ to design parts for additive and to understand the materials and how the process and the machines work.”

“We don’t consider ourselves strictly as service providers. We want to understand the whole AM process, include added-value into metal AM parts like functional integration, lightweight construction and support our customers in design for AM,” Hansen says. “We help our customers to learn how to ‘think additive,’ to design parts for additive and to understand the materials and how the process and the machines work. We offer training, advice and support in parameter development for companies who own a 3D printer, but do not have the expertise to run them efficiently.”

“Our goal is to be globally known as ‘Center of Excellence in AM,’ to be the first point of contact for companies seeking advice in anything related to additive manufacturing,” Hansen concludes. “We are about to have our AM processes TÜV-certified and with our partnership with Additive Industries and collaborations with universities, as well as four engineers dedicated to AM we have set up engineering capability and technology know-how to understand and control processes in-depth.”

Related Content

Video: AM for Harder, Longer-Lasting Brake Discs

Additive manufacturing is being applied to limit automotive brake dust. For a major automaker, Etxetar and Talens are developing a production-speed directed energy deposition system to give brake discs a precise layer of wear-resistant carbide.

Read MoreWhat Holds AM Back in Automotive Production? GM Additive Lead Describes Advances Needed

“If AM were cheaper, we would be doing more of it,” says GM’s Paul Wolcott. Various important factors relate to cost. However, the driving factor affecting cost is speed.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreRead Next

How to Accelerate Industrial Additive Manufacturing

The 2018 Additive World Conference was dedicated to industrial additive manufacturing and covered all relevant topics from the fields of 3D design, simulation, manufacturing and materials as well as case studies.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More