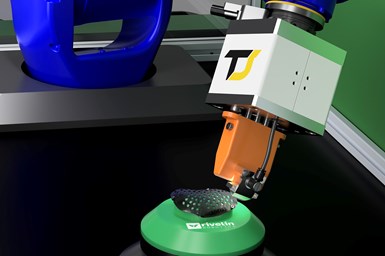

Rivelin Robotics’ Netshape Robots for Metal AM Postprocessing

Formnext 2022: NetShape Robots are designed to provide an automated solution for metal support removal and targeted finishing to meet the standards of mission-critical industries.

Rivelin Robotics’ NetShape Robots were developed to address the need for fast, reliable postprocessing solutions for metal AM parts and components. According to the company, for many metal AM applications, postprocessing contributes nearly 30% of unit cost per part, often involving manual intervention which introduces part-to-part quality inconsistency. In addition, it can be a costly, laborious and, in some instances, hazardous part of the production workflow.

[Related: Force sensing and vision in the Rivelin Robotics postprocessing system (includes video)]

The NetShape Robot provides an automated solution for metal support removal and targeted finishing to meet the standards of mission-critical industries. Driven by Rivelin’s NetShape control software, both machine learning and traditional deterministic control theory are used to optimize the quality and repeatability of support removal and finishing. The result is an automated support removal solution that is said to reduce defects by 90%, exhibits a 10-fold reduction in operational costs, and eliminates human risk and variability.

“The search for automated postprocessing solutions is ongoing and vital for the mass uptake of metal AM across industry, and is the reason that Rivelin Robotics exists,” says Robert Bush, Rivelin Robotics CEO. “As a company, we aim to drive the uptake of AM which we see as a major contributor to a sustainable future, and which will have lasting benefits for our environment. With NetShape Robots, we introduce our first breakthrough to achieve this goal.”

NetShape Robots can be applied to the specifics of customer applications, including automation of common metal AM postprocessing tasks which can protect workers’ health, tackle skills shortages and reduce costs.

Related Content

-

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

-

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

-

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.