Quantica Adds AI-based MultiSlice Software to Multimaterial 3D Printing System

The software offers a reliable simulation of 3D models for printing, providing a straightforward pathway to accurately manufacture multimaterial end products.

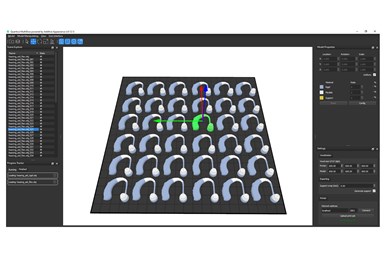

Quantica has added AI-based MultiSlice software to its NovoJet Open printhead technology to enable the reliable simulation of 3D models for multimaterial 3D printing. With NovoJet Open technology, it is users can combine functional materials on a voxel level to produce final parts in a single printing process.

For this reason, Berlin-based Quantica collaborated with Additive Appearance (a Charles University spin-off company) to offer a software solution that addresses the challenge of seamlessly combining multiple materials, which is a critical aspect when designing any application with specific requirements on properties.

Offering a reliable simulation of 3D models for printing, the software provides a straightforward pathway to accurately manufacture multimaterial end products.

MultiSlice: From Shape to Appearance and Function

The MultiSlice build management and slicing software combined with the NovoJet Open printing system enables users to produce objects that go beyond mere shape replication. Additionally, this includes replicating both appearance and function. Harnessing the potential of simulations and drawing on the distinctive expertise of computer graphics researchers in the mathematics and physics department at Charles University, the software utilizes advanced algorithms to predict the appearance of a 3D model with a high level of accuracy.

MultiSlice will be introduced with the first NovoJet Open systems early 2024. The two teams plan to develop the technology in multiple iterations toward different levels of sophistication with regard to the control of physical properties on a voxel level. These will include mechanical properties like flexibility and conductivity, appearance properties like color, and the ability to transition between them.

“Both our companies, embodying the agility of startups, are uniting to redefine the potential of 3D material jetting. In a landscape where functional, multimaterial 3D printing lacks adequate software, we are excited to collaborate with a team that is leveraging modern approaches to developing complex software,” says Grace Chang, Quantica’s head of product management. “Our collaborative goal is to leverage these advancements, making functional, multimaterial 3D printing more accessible, efficient and adaptable.”

Leveraging the potential of artificial intelligence (AI) and the technology it is based upon — differentiable programming — the team at Additive Appearance has created novel approaches to enduring problems in the printing industry such as halftoning and print preview. Following years of academic research, they have published multiple scientific papers in top-tier journals. One publication is presenting an approximative but faster print preview using a neural network. In concurrent work, a halftoning method based on differentiable programming is described.

“With the trend in 3D printing going to more and more printheads, existing software is starting to limit the hardware’s potential. The problem of which material to put in which voxel is getting increasingly difficult,” says Tobias Rittig, Ph.D., Additive Appearance’s chief technology officer. “This is why a radically new approach based on cutting-edge research and modern software technologies, such as differentiable computation and machine learning, is required to drive the printers of the future. We both share this realization and are looking to create a synergy of software and hardware that unlocks many new possibilities in the material jetting domain.”

Quantica says its NovoJet technology transforms high-viscosity materials into multimaterial end-use parts, delivering high-performance prints with exceptional properties in a single process.

- Listen to this episode of AM Radio to hear about Quantica’s 3D printing jetting head at RAPID + TCT 2022. Editors Stephanie Hendrixson, Peter Zelinski and Julia Hider share observations, insights and photos from the 2022 RAPID + TCT trade show.

Related Content

Implicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreHybrid Additive Manufacturing Improves Debarking Knife Tip Strength and Production Efficiency

Nicholson Manufacturing chose the Mastercam APlus specialized add-on to unlock hybrid manufacturing for making its debarker knife tips, enabling it to add durable layers to the wear surfaces of the tips to make them more resilient while also making the production process more efficient.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More