PolySpectra Reformulates Rugged Resin for Desktop 3D Printers

COR Alpha was previously available solely for use on 385-nm wavelength 3D printers, limiting use to industrial hardware. The new formulation expands availability to 405-nm wavelength systems.

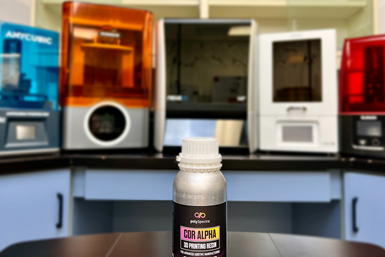

COR Alpha resin is now available in 405-nm wavelength formulation, which is suitable for desktop 3D printers. Photo Credit: polySpectra

PolySpectra, maker of rugged photopolymer resins, has created a new formulation of its flagship material that is compatible with desktop digital light processing (DLP) and liquid crystal display (LCD) resin 3D printers. Previously available solely for use on 385-nm wavelength 3D printers, limiting use to industrial hardware, the new formulation expands availability to 405-nm wavelength systems for additive manufacturing.

“We founded polySpectra with a mission to democratize manufacturing,” says Raymond Weitekamp, PhD., polySpectra founder and CEO. “Today, we are very excited to announce the 405-nm version of COR Alpha – which now gives engineers the ability to access the world's most rugged photopolymers on a wide array of resin 3D printers spanning every price point.

Real End-Use 3D Printing

While many “production-grade” resins available today for 3D printing can create high-resolution parts with unique geometric complexity, the company says they are often too brittle for demanding real-world applications. This inherently limits their use to prototyping and other less-demanding use cases.

COR stands for “Cyclic Olefin Resin,” a family of engineering-grade materials for AM developed by polySpectra. COR Alpha relies on Nobel-winning chemistry to offer durability, high-impact strength, high-temperature performance, and moisture- and chemical-resistant capabilities — all without brittleness. Satellite components, consumer products, electronics connectors and highly durable tooling for injection molding are just a few of the high-value applications where the company says COR Alpha can tip the scale from prototyping to production.

COR Alpha has been commercially available since 2022 in a 385-nm wavelength version which is compatible with and validated on a catalog of industrial-grade 3D printers.

This new formulation makes rugged AM more accessible. It is said the COR Alpha resin 405-nm formulation dramatically expands the list of compatible 3D printers. For the first time, inexpensive desktop 3D printers will have the capability to print with truly rugged resin. R&D labs, small businesses without industrial budgets and other users — many who already own desktop 3D printers — now gain the ability to create end-use parts in-house.

“The only difference between a toy and a tool is what it can produce,” Weitekamp says. “Whether you are running a $250 LCD printer or a $250,000 DLP machine, COR Alpha unlocks a step change in ROI.”

As of launch, 405-nm COR Alpha is fully validated for use on Asiga 3D printers. Additionally, many of the bestselling desktop 3D printer models are on the list of polySpectra’s exploratory 3D printers, including systems from Anycubic, Elegoo, Nexa3D, Phrozen, and Shining3D.

Over the next few weeks, polySpectra will announce validated print profiles for COR Alpha for many specific 3D printer models, in collaboration with these hardware manufacturers and others.

- Read how polySpectra is embracing augmented reality (AR) with a new tool called Massless intended to reduce unnecessary 3D printing.

- Listen to this episode of AM Radio to hear about parts printed from polySpectra COR resin and other odd-looking parts created using Metafold 3D software.

Related Content

ActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read More3D Printed Lattices Replace Foam for Customized Helmet Padding: The Cool Parts Show #62

“Digital materials” resulting from engineered flexible polymer structures made through additive manufacturing are tunable to the application and can be tailored to the head of the wearer.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreAirless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More