Incus Develops Hammer Pro40 for Larger Build Volumes

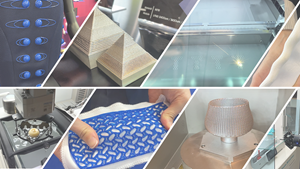

Formnext 2023: The Hammer Pro40 metal 3D printer has a platform six times larger than its smaller Hammer Lab35 predecessor.

Incus, an Austrian provider of lithography-based solutions for metal additive manufacturing (AM), has developed the Hammer Pro40 printing solution for mass manufacturing. Building on the principles of its Hammer Lab35 printing system, the Hammer Pro40 offers upgraded production capabilities, while maintaining the same level of expertise and familiar technology.

The system’s larger build volume is achieved by two moving or scrolling projectors (instead of one stationary projector) without loss of accuracy. With a platform six times larger than its smaller Hammer Lab35 predecessor, the Hammer Pro40 bridges the gap to mass manufacturing. With a high potential throughput of 700 cm³/hr and resolution with a pixel pitch of 40 micron in X/Y, the Hammer Pro40 enables print economics while delivering the geometries and surface aesthetics of the Incus technology.

The Hammer Pro40 is engineered to manufacture large batches of intricate, specialty parts in applications ranging from dental, medical, automotive, microrobotics and jewelry. With a printing speed that is seven times faster than the Hammer Lab35 and a printing cost per cubic meter that is four times lower, the new machine delivers unmatched cost efficiency without compromising on quality.

With surface roughness (Ra) of 2 microns after sintering, the Pro40 eliminates the need for additional surface treatments like polishing or sandblasting. With a high green part strength, the handling of the green parts can easily be automated. The machine is designed to operate several jobs without the need for intervention from the operator and includes a feedstock supply for at least 2-3 days. Job preparation, setup and material changeover are streamlined, taking less than five minutes, ensuring that the printing process remains seamless and uninterrupted.

“The Hammer Pro40 was strategically developed to fulfill the growing demand for mass manufacturing with AM while still delivering the unique features of our technology,” says Dr. Gerald Mitteramskogler, Incus CEO. “This innovation means a leap forward in terms of speed, precision and cost-effectiveness, but it also opens up new opportunities to leverage the versatility of our manufacturing solution. Within a single print, you can create intricate medical gripping devices, patient-specific dental brackets, personalized jewelry pieces, prototypes for electronic devices, and customized automotive knobs for luxury interior designs — all in quantities ranging from single prototypes to mass manufacturing."

- Read about Incus’ successful testing of lithography-based metal manufacturing for the lunar environment. The project aim was to develop a sustainable process that uses lunar resources and recycled scrap metals (eventually contaminated by lunar dust) to produce spare parts on-site which could help and enhance human settlement on the moon.

- Learn more about the Incus Hammer Lab35 which offers economic prototyping, small-scale production. The metal 3D printer has potential to increase performance and reduce costs for small and mid-scale production, as well as manufacture parts featuring complex geometries.

Related Content

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read More8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read More10 Video Reports From Formnext 2023

Our Formnext video playlist: Stephanie Hendrixson and Peter Zelinski report on various technologies seen at Formnext 2023 in brief videos they filmed at the show.

Read MoreAssonic Develops Automated System for Processing Reactive Metal Powders Without Gas Loss

Formnext 2024: The Assonic SPC 500 system features a closed circuit for conveying both powder and gas to eliminate gas loss while processing reactive metal powders in additive manufacturing.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More