1000 Kelvin’s AMAIZE AI Co-Pilot for Additive Manufacturing Now Available for Autodesk Fusion

The AMAIZE software is an “AI co-pilot” for engineers, predicting print issues upfront, performing corrections and generating industrial-grade, ready-to-use print files specific to a machine.

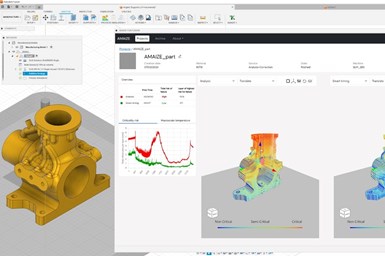

1000 Kelvin’s AMAIZE is now integrated in Autodesk Fusion 360, enabling engineers to analyze and correct their AM designs seamlessly. Source: 1000 Kelvin

1000 Kelvin, a developer of AI co-pilots for additive manufacturing (AM), now offers its AMAIZE AI co-pilot as a plug-in for Autodesk’s Fusion integrated CAD/CAM software platform. AMAIZE enables design and manufacturing companies to 3D print complex components quickly and efficiently.

AMAIZE uses machine learning models informed by physics and manufacturing data to predict design and print issues, and output optimal print files that result in successful prints. As a result, engineers using AM can eliminate physical trial-and-error cycles, and handle more complex parts which would otherwise require extensive and time-consuming design iterations. AMAIZE is now available to download today from the Autodesk App Store.

“Availability of AMAIZE on the Autodesk App Store is set to transform manufacturing operations,” says Katharina Eissing, Ph.D., 1000 Kelvin CTO and co-founder. “This integration will improve manufacturing productivity by increasing uptime, significantly reducing lead times, bolstering process stability and expediting the training process for staff to gain expertise in 3D printing.”

These improvements are particularly beneficial for precision AM companies that are facing challenges due to escalating costs and an aging workforce.

“One of AI’s greatest benefits is its ability to simplify complex processes, expanding access to powerful technology beyond a small circle of domain experts,” says Stephen Hooper, Autodesk vice president, Design and Manufacturing Product Development. “By automating the setup and programming of industrial-grade print processes, 1000 Kelvin’s AI, integrated with Autodesk Fusion in the cloud, unlocks the opportunity for a much broader pool of professionals to be successful with additive manufacturing.”

The software helps additive manufacturers reduce the time and cost of printing high-quality metal parts. The company’s AMAIZE software is the “AI co-pilot” for engineers, predicting print issues upfront, performing corrections and generating industrial-grade, ready-to-use print files specific to a machine. AMAIZE uses machine learning models to predict print challenges and correct them directly in the print file, increasing the number of prints that are perfect on the first try.

“One of the main challenges in the manufacturing industry, and especially the U.S. today, is the talent shortage, which is holding companies back from scaling to fulfill fast-growing demand in the market,” says Omar Fergani, 1000 Kelvin CEO and co-founder. “Our AI co-pilot AMAIZE is an enabler to overcoming this hurdle, helping companies secure their know-how.”

Related Content

-

5 Observations From Dr. Tim Simpson About the State of Additive Manufacturing So Far

The outgoing co-director of Penn State’s CIMP-3D takes stock of how far AM has come, aided in no small part through the work of the organization he helped to lead.

-

Hexagon Invests in Divergent’s Autonomous, Sustainable Manufacturing

The Divergent Adaptive Production System (DAPS) is a fully integrated software and hardware solution, creating a complete modular digital factory that combines AI-optimized generative design software, additive manufacturing and automated assembly to build lightweight automotive parts and frames.

-

Carnegie Mellon Helps Industry, Students Prepare for a Manufacturing Future with AM and AI

Work underway at the university’s Next Manufacturing Center and Manufacturing Futures Institute is helping industrial additive manufacturers achieve success today, while applying artificial intelligence, surrogate modeling and more to solve the problems of the future.