Titan, Jabil Customize Formulations for Pellet Extrusion 3D Printing

Partnership qualifies and integrates customized materials for use on Titan’s pellet-based Atlas 3D printers to produce stronger, lighter and more flexible parts.

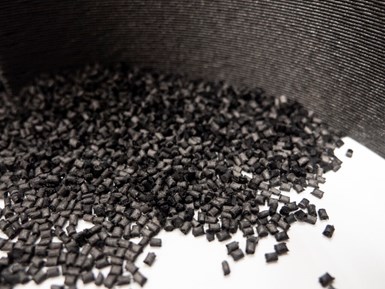

Titan and Jabil are testing and validating new pellet formulations of Jabil’s carbon fiber-reinforced nylon materials, which are designed to produce stronger, lighter and more flexible parts.

Titan Robotics is collaborating with Jabil Inc. to accelerate the adoption of large-format, industrial additive manufacturing (AM). Jabil Engineered Materials, a unit of Jabil which develops polymer formulations and compounds, is working with Titan to qualify and integrate customized AM materials for use on Titan’s pellet-based Atlas 3D printers.

The companies are working together to drive the production of large-format tooling for applications in sheet metal forming, composite layups, welding fixtures, molding, casting patterns and end-use parts on Titan Atlas printers in order to meet a growing need for increased part strength and faster printing speeds. Jabil is combining its specialized materials science expertise with Titan’s robust printing performance to address a growing number of rigorous industrial, medical, defense and aerospace applications.

“Titan and Jabil are fulfilling a joint mission to move additive manufacturing into serial production and advanced manufacturing,” says Bill Macy, Titan Robotics partner and CTO. “By choosing Jabil’s engineered materials customized for applications with high-throughput pellet printing on the Atlas, we can help customers reduce costs, create products with mass customization, reduce cycle times and innovate quickly.”

Titan and Jabil are testing and validating new pellet formulations of Jabil’s carbon fiber-reinforced nylon materials, which are designed to produce stronger, lighter and more flexible parts. “Jabil takes a polymer science approach to developing engineered materials,” says Matt Torosian, director of additive product management at Jabil. “All of our materials are designed exclusively for additive manufacturing, so Titan receives pellets that embody all the necessary attributes to optimize performance and reliability.”

According to the companies, the collaboration gives customers greater choices from a wide variety of high-performance pellet materials as well as the opportunity to create custom compounds to address specific requirements. This partnership validates materials before customers print extremely large and costly, high-end final parts.

Related Content

-

Combining Multifunctional Thermoplastic Composites, Additive Manufacturing for Next-Gen Airframe Structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Video: 3D Printed Hand Tools in Action on Pella Corporation Factory Tour

Examples include an invention for quickly installing window and door weather stripping, a fitting for giving the proper angle to a nail gun, and a clip for which the color is an important feature.

-

When Advocacy Leads to Adoption: How Pella Applies (and Manages) AM Capacity

The window and door maker offers a picture of successful, widespread 3D printing adoption across the different needs of a manufacturing organization. The outreach and education effort worked. Now, here is the next phase.