Avio Aero, BeamIt Group, GE Additive Collaborating on Additive Manufacturing Technology

GE Additive to become BeamIt’s strategic equipment supplier moving forward.

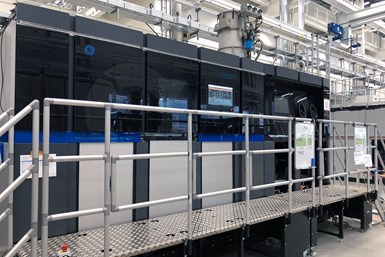

GE Additive Concept Laser M Line factory. Photo Credit: Wilm Visuals for GE Additive

Avio Aero and GE Additive have signed a nonbinding letter of intent outlining a strategic technology collaboration agreement with BeamIt Group, which is partly owned by Sandvik.

BeamIt is collaborating with Avio Aero on technology development and, in particular, the postprocessing of certain additively manufactured (AM) components for the GE9X and the Catalyst engines.

BeamIt is a longstanding GE Additive customer and operates a fleet of Concept Laser and Arcam EBM machines, including the Mlab, M2 and X Line platforms, as well as two Q10plus machines across its subsidiaries — Pres-X and Zare — serving customers in multiple industries, including aerospace, defense and medical.

The intention is for GE Additive and BeamIt to cooperate on a number of strategic projects, such as special postprocessing machinery and technologies as well as materials, to meet long-term production needs.

GE Additive would become BeamIt’s strategic equipment supplier, as it continues to scale its operations and enhances its existing facilities to meet long-term production needs.

The agreement includes collaboration and assessment on postprocessing technologies for the specific requirements of certain GE9X and Catalyst engine components, such as MRI and tomographic inspection, HIP and machining equipment. BeamIt would contribute to the reduction of the lead times necessary to build components, including machining and testing processes, and it would also support new modalities under development at Avio Aero with super-cleaning and super-finishing surfaces.

BeamIt would also support in the development of GE Additive’s Concept Laser M Line Factory system. The M Line is a highly advanced, industrialized production system that is best-suited to experienced metal additive users who have already started to scale production volumes, the company says. M Line’s stitching capability is said to enable customers with large part size demand to increase productivity and drive cost down for additive production.

Related Content

-

With Electrochemical Additive Manufacturing (ECAM), Cooling Technology Is Advancing by Degrees

San Diego-based Fabric8Labs is applying electroplating chemistries and DLP-style machines to 3D print cold plates for the semiconductor industry in pure copper. These complex geometries combined with the rise of liquid cooling systems promise significant improvements for thermal management.

-

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

-

AM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.