American Precision Museum Launches Interactive Digital Exhibit

Support and inspire the future of manufacturing by honoring a manufacturing innovator, advocate or educator in new exhibit.

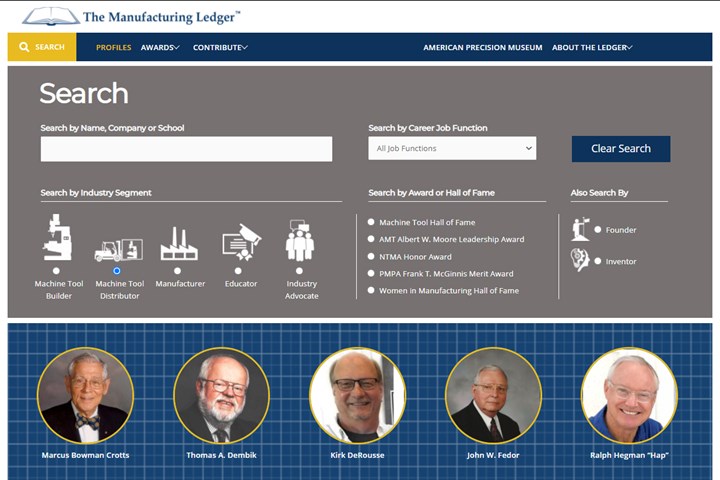

The Manufacturing Ledger enables visitors to sort by industry sector, lifetime achievement awards or inventors and founders. Visitors can also search by name, company and job function.

The American Precision Museum (APM) recently launched a new interactive digital exhibit called “The Manufacturing Ledger.” The exhibit is a collection of stories and profiles about individuals whose careers were devoted to manufacturing — whether the person’s career was spent on the shop floor, engineering department, sales department or in the corporate boardroom.

The exhibit — which is designed to support and inspire the future of manufacturing — is accessible online and will soon be integrated into a physical exhibit at the museum.

The Manufacturing Ledger embraces the “people” aspect of the manufacturing history, enabling the APM to tell the full narrative of manufacturing by providing a well-designed framework and functional platform to relay sponsored profiles and pictures of an infinite number of individuals. The museum welcomes submissions from a variety of manufacturing career categories, including machine tool builder, machine tool distributor/importer, manufacturer, educator and industry advocate (such as associations, media).

APM says interacting with the exhibit is easy and cross-referenced, enabling visitors to sort profiles by industry sector, job function, name and company so visitors can find former co-workers and learn more about their career path. There are also search functions to locate those who founded a company or who invented a technology used in manufacturing. Visitors can also search by various lifetime achievement awards from participating associations, such as AMT – The Association for Manufacturing Technology, National Tooling & Machining Association (NTMA), Precision Machined Products Association (PMPA) and Women in Manufacturing (WiM) as well as members of the Machine Tool Hall of Fame.

Participating in The Manufacturing Ledger supports the American Precision Museum financially and physically. Contributing your story or that of a family member, friend, colleague, mentor or educator enriches the content of the exhibit itself, while financial donations sponsoring each profile help fund the museum. The facility maintains the largest collection of historically significant machine tools in the nation, all housed in an 1846 armory building which is designated a National Historic Landmark.

The museum’s goals are to preserve, present and interpret its artifact collections and property; to inspire new generations of innovators; and build communities that foster a strong manufacturing future.

“The American Precision Museum is home to remarkable manufacturing breakthroughs,” says Lee Morris, chairman of Morris Group Inc. “To produce precise, interchangeable rifle componentry, engineering innovators replaced manual filing and fitting with water-powered, metal cutting machine tools of their own design. It is doubtful that these engineers had any idea of the impact of their creativity. They were at the forefront of a manufacturing revolution, but their individual stories are mostly lost. The progress of every decade since, is the product of people thinking, creating and improving in response to perceived opportunity. The story is repeated time and again. It’s the people behind manufacturing innovations who are so compelling. Along with the machinery that they have created, we also need to collect, share and preserve personal stories of the manufacturing innovators who have so strongly influenced the United States throughout the years.”

To begin the process of contributing your unique manufacturing story or to honor someone you know, visit The Manufacturing Ledger. For further information, contact Steve Dalessio at 802-674-5781 or ledger@americanprecision.org.

Related Content

The Connector Conundrum: 3D Printed Mold Tooling’s Role in Innovation

ReelView Fishing faced an electronics obstacle in the development of its new technology for underwater video. Additive manufacturing for moldmaking allowed for the speed necessary to iterate to a solution. How inventors and invention will benefit from new ways of obtaining production-ready tooling.

Read More6 Considerations When Launching an Additive Startup

Recent additive manufacturing (AM) startup owner, JP Kinerk, shares his experience by offering helpful advice for others just starting out in the additive realm.

Read MoreFluent Metal Startup Launches With Focus on Liquid Metal 3D Printing

The company says its drop-on-demand technology can enable sustainable, production-grade additive manufacturing using high-value metal components.

Read MoreResearchers Develop Resin for 3D Printing Implants for Cataracts, Other Eye Conditions

The ability to 3D print intraocular devices for treating cataracts and other eye conditions could significantly enhance eye care for patients by offering unparalleled levels of customization and design precision, potentially leading to better clinical outcomes.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More