Variable Resistance Valve Trim Achieves Lead Time Reduction Through AM: The Cool Parts Show #69

Baker Hughes is realizing shorter lead times and simplified manufacturing through powder bed fusion to produce valve trims previously assembled from many machined metal parts.

Share

Scroll to unlock this premium content if video does not play.

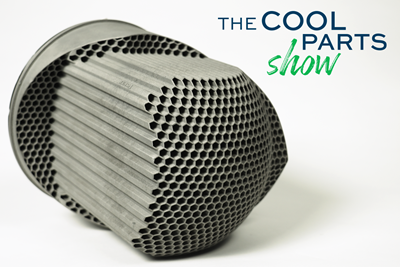

Industrial valve components supplied by Baker Hughes include a line of variable resistance trim stacks that alleviate cavitation when installed in reciprocating valves. In the past, these parts have literally been stacks — pieces of metal drilled, stacked and brazed together to create the tortuous geometry that counters pressure drop and prevents cavitation bubbles from forming. The manufacturing process was lengthy and involved multiple steps and suppliers. By converting these parts to additive manufacturing via laser powder bed fusion instead, the company is realizing the benefits of assembly consolidation and a shorter supply chain. Now, variable resistance trim stacks can be produced almost entirely in-house, in just a couple of weeks. Each production released part now has a Golden Master Manufacturing router that contains its golden design file, build setup file, postprocessing instructions and inspection instructions so that trims can be reproduced quickly and consistently. These parts won the Production category for The Cool Parts Showcase in 2023.| This episode of The Cool Parts Show is sponsored by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related Resources

- Additive manufacturing versus cavitation

- More about the finalists and winners of The Cool Parts Showcase in 2023

- Another anti-cavitation device that is now 3D printed

Transcript

00:00:00:00 - 00:00:00:23

Pete Zelinski

I’m Pete.

00:00:00:23 - 00:00:06:03

Stephanie Hendrixson

I'm Stephanie. And this is The Cool Parts Show our show all about cool, innovative 3D printed parts.

00:00:06:03 - 00:00:08:08

Pete Zelinski

These valve components

00:00:08:08 - 00:00:15:17

Pete Zelinski

used to be crazy difficult to produce made of machined parts that were stacked together and then assembled by brazing,

00:00:15:17 - 00:00:18:09

Pete Zelinski

soldering basically, it took a long time.

00:00:18:09 - 00:00:22:12

Stephanie Hendrixson

Now these parts are 3D printed all in one go. It's faster,

00:00:22:12 - 00:00:24:19

Stephanie Hendrixson

and very little redesign was needed.

00:00:24:19 - 00:00:25:22

Pete Zelinski

Bonus,

00:00:25:22 - 00:00:33:23

Pete Zelinski

This is the best production part winner in our contest, the Cool Parts Showcase. That's all coming up right after this.

00:00:38:16 - 00:00:48:13

Unknown

The Cool Parts Show is brought to you by Carpenter Additive. When it comes to managing metal powder, there is no one size fits all approach. Stick around after the episode to learn more.

00:00:48:13 - 00:00:51:04

Pete Zelinski

Welcome to The Cool Parts Show.

00:00:51:04 - 00:01:09:20

Stephanie Hendrixson

If you like the show, make sure to subscribe on YouTube. And as a reminder, you can also join our All Access newsletter for early access to videos like this and lots more content. Today on the show we are looking at these parts. These are special parts because they were the best production part in our Cool Parts Showcase for 2023.

00:01:09:20 - 00:01:22:07

Stephanie Hendrixson

So we have several parts on the table with us. These are all different variations, basically different same products in the same line. They are variable resistance, trim stacks. These are industrial valve components and they were produced, designed,

00:01:22:07 - 00:01:23:23

Stephanie Hendrixson

submitted to us by Baker Hughes.

00:01:23:23 - 00:01:42:14

Pete Zelinski

Baker Hughes, major manufacturer of high end valves, among other industrial components, also a company that is leaning into additive manufacturing as a mode of production. As we're going to learn this valve component, it's a success for additive manufacturing, not just in terms of the geometry

00:01:42:14 - 00:01:58:15

Pete Zelinski

that 3D printing is able to realize. It's also a production success because of the way the Baker Hughes team is managing a high variability, high mix component and scaling up with that into production.

00:01:58:15 - 00:02:01:21

Pete Zelinski

But first, let's learn about this component, what it does.

00:02:01:21 - 00:02:10:01

Stephanie Hendrixson

So to tell us more about cavitation and how these trims work, I want to introduce Rebecca O'Donnell. She is a senior product engineer at Baker Hughes.

00:02:10:01 - 00:02:18:01

Rebecca O'Donnell

A variable resistance trim stack is basically a retainer that fits inside of a reciprocating valve.

00:02:18:03 - 00:02:37:05

Rebecca O'Donnell

And it's purpose is to alleviate cavitation within the valve. It's made with a series of stacks that break up the pressure drop throughout the flow of the fluid. And so it therefore eliminates cavitation within the valve itself.

00:02:37:05 - 00:02:47:20

Rebecca O'Donnell

So cavitation is basically when a liquid drops below, it's vapor pressure forming bubbles. Those bubbles, then when the pressure recovers, implode.

00:02:47:20 - 00:03:00:08

Rebecca O'Donnell

And what happens with those bubbles when they implode is they experience a micro jet against a metal boundary. And that can be particularly damaging to downstream pipe as well as inside of the valve.

00:03:00:10 - 00:03:07:06

Rebecca O'Donnell

So at all costs, we try to avoid cavitation and that's where the VRT or variable resistance

00:03:07:06 - 00:03:11:10

Rebecca O'Donnell

trim comes into play. It eliminates the cavitation

00:03:11:10 - 00:03:43:11

Stephanie Hendrixson

So we've said the name of this part a couple of times, Variable resistance trim stack. The part is variable because these holes that you see change location as you move through the part from top to bottom, that is how the trim stack resists cavitation inside of the valve as part of the trim. And they refer to this as a stack because even though the ones that we have in front of us were all 3D printed as single pieces previously, when these parts were made, they would have literally been a stack of metal plates with holes drilled through them that were all braised and assembled together.

00:03:43:11 - 00:03:57:11

Pete Zelinski

For a picture of what that was like, the way these components used to be made. I want to bring in another voice. This is Mikael and this. I'm off. He's additive manufacturing customer engagement leader.

00:03:57:11 - 00:04:14:00

Mikhail Anisimov

These variable resistance trim components were conventionally manufactured as a stack of plates with drilled holes that had to be brazed together and then machined to a final state involving multiple vendors along the production cycle.

00:04:14:00 - 00:04:26:12

Mikhail Anisimov

The required coordination across all the steps was essential and it regularly resulted in some delays because new vendors were added.

00:04:26:12 - 00:04:35:00

Rebecca O'Donnell

In each one of those manufacturing steps, you have a risk of something going wrong. Maybe something's machined out of tolerance,

00:04:35:00 - 00:04:38:16

Rebecca O'Donnell

and it takes time to machine all the disks.

00:04:38:16 - 00:04:46:15

Rebecca O'Donnell

Then when you send it out to a third party, you have an issue where you're at the mercy of the third party supplier.

00:04:46:21 - 00:04:55:16

Rebecca O'Donnell

The purpose of doing the 3D printing is to make sure that we have total control of the part throughout

00:04:55:16 - 00:04:58:16

Rebecca O'Donnell

and we monitor the quality and the leadtimes.

00:04:58:16 - 00:05:06:18

Stephanie Hendrixson

So previously these parts were made through a lot of assembly and that was challenging, not just because there were multiple different parts

00:05:06:18 - 00:05:20:06

Stephanie Hendrixson

that had to be joined together, but also because Baker Hughes was working with multiple different suppliers. They were all doing different parts of this process, and each of those steps took time. And so actually one of the big drivers behind looking at additive manufacturing for these components

00:05:20:06 - 00:05:23:13

Stephanie Hendrixson

was reducing that lead time, trying to get these components faster.

00:05:23:13 - 00:05:28:14

Pete Zelinski

Yeah, machining was done in one place, brazing was done someplace else.

00:05:28:18 - 00:05:58:10

Pete Zelinski

Even the machining there were different operations, different stations, and so there were all of these different subcomponents or subassemblies moving from station to station, moving from supplier to supplier. Inevitably there was some delay at every single stop. It was very difficult to schedule all of that. And as a result, Baker Hughes was stuck. They were stuck with having to quote, long lead times to their customers for these parts.

00:05:58:10 - 00:06:17:20

Pete Zelinski

Now, by comparison, these components are made essentially all in one piece through additive manufacturing on machines located in Baker Hughes’ own facility in Houston, Texas. So the company has taken control of the process, taken control of that lead time. That is a huge change.

00:06:17:20 - 00:06:20:04

Stephanie Hendrixson

Yeah. So a huge change in how these

00:06:20:04 - 00:06:28:03

Stephanie Hendrixson

components are manufactured from the timeline to where the manufacturing process steps happen, but actually not a huge change in terms of the design.

00:06:28:03 - 00:06:31:08

Pete Zelinski

So with additive manufacturing, we are so accustomed to

00:06:31:08 - 00:06:49:07

Pete Zelinski

the 3D printed part being this organic form that looks very different from the components that it replaced. That's not the case with this. Like this is a 3D printed part, but you look inside it and the logic of the stack configuration is still there.

00:06:49:07 - 00:06:52:22

Pete Zelinski

It still geometrically resembles the previous component.

00:06:53:01 - 00:07:04:18

Pete Zelinski

I want to bring in one more voice because this is somebody who was instrumental in translating this part, the design of this part into the current additive manufactured form. This is

00:07:04:18 - 00:07:08:17

Pete Zelinski

Rohan Buntval for additive manufacturing design engineer,

00:07:08:17 - 00:07:34:00

Rohan Buntval

When the Valves group places an order for a new VRT with the additive group, the first thing we do is we take the models or the assembly and we consolidate the whole stack into a single body. We remove any vestigial assembly features such as alignment pin holes or plate markings that might be used to identify the individual plates.

00:07:34:00 - 00:07:50:08

Rohan Buntval

after we finalize the model, we then create the engineering drawings that detail the machining and post-processing requirements, and we put it through a review and release process in our product lifecycle management software or our PLM system.

00:07:50:08 - 00:07:59:18

Rohan Buntval

Every AM part that comes to us has a unique additive art number and is revision control and this is one of our requirements as an ISO certified facility.

00:08:00:14 - 00:08:12:01

Stephanie Hendrixson

So even though these valve components look pretty similar to the ones they replace, there is a little bit of development work. There are some changes that have to be made to make these into something that can be produced through laser power bed fusion.

00:08:12:05 - 00:08:15:02

Pete Zelinski

Laser powder bed fusion. So let's talk about how these are made.

00:08:15:02 - 00:08:19:17

Pete Zelinski

The material is inconel, a nickel based metal alloy.

00:08:19:17 - 00:08:29:18

Pete Zelinski

And these components come in a broad range of sizes, as you can see, from one inch in diameter to 12 inches in diameter.

00:08:29:18 - 00:08:36:09

Stephanie Hendrixson

And so every time Baker Hughes is faced with converting one size or configuration of these valve trims

00:08:36:09 - 00:08:39:21

Stephanie Hendrixson

for additive manufacturing, there are some steps that they have to go through.

00:08:40:02 - 00:08:48:01

Stephanie Hendrixson

So there is that process that Rohan described of looking for those vestigial features from assembly and removing them.

00:08:48:04 - 00:08:59:02

Stephanie Hendrixson

But in some cases they're actually looking for chances to preserve some of the features from the previous versions. So for instance, inside of these valve trims, there are these sort of slots

00:08:59:02 - 00:09:10:15

Stephanie Hendrixson

which would come from that sort of stacked structure in the conventional version. They wanted to maintain that, but these slots would be difficult to 3D print on certain angles of the part.

00:09:10:17 - 00:09:33:03

Stephanie Hendrixson

And so you would need lots of little support structures in there and then you would have to go in and remove all those little support structures. So their solution was to make the inner diameter of this part a little bit smaller, add a little bit of extra material. And for the places where it would be difficult or impossible to support those slots, what they do instead is print these little structures that look like airplane windows.

00:09:33:05 - 00:09:39:01

Stephanie Hendrixson

So these are smaller holes that still allow for the powder to escape, but they don't need to be supported

00:09:39:01 - 00:09:43:20

Stephanie Hendrixson

because Baker Hughes knows that they are going to machine the internal diameter

00:09:43:20 - 00:09:47:11

Stephanie Hendrixson

and they can remove that material and open up those slots after the fact.

00:09:47:19 - 00:09:56:16

Pete Zelinski

So yeah, there are some straightforward post-processing steps and the fact that they know post-processing is coming actually simplifying the design for 3D printing.

00:09:56:23 - 00:10:08:13

Pete Zelinski

There's cut off the parts are cut off the build plate with a band saw. There's de-powdering. Heat treating. This outer diameter is machined on a lathe and then

00:10:08:13 - 00:10:15:10

Pete Zelinski

very precise machining related to this inner diameter. And it's that step actually, that opens up those airplane windows.

00:10:15:10 - 00:10:22:13

Unknown

So there are still plenty of steps in manufacturing this part. But the difference now is that almost all of them are taking place at Baker Hughes.

00:10:22:13 - 00:10:53:03

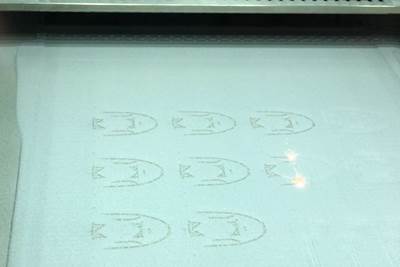

Pete Zelinski

And previously there were a lot more steps than that and they were spread out across various different suppliers. And now all of that value is concentrated into one additive manufacturing cycle on one build plate. And in fact, it's better than that because all of that value for various different parts is concentrated into one cycle on one build plate, because typically Baker Hughes is now 3D printing multiple valve trims at once.

00:10:53:03 - 00:11:00:15

Stephanie Hendrixson

And so they've put a lot of effort into trying to capture all of this development, all of this value that they've put into these 3D printed parts.

00:11:00:15 - 00:11:15:01

Stephanie Hendrixson

Once they have a good print file for any new valve trim that they're working on, they lock it down and they store it away so that the next time a customer needs exactly this valve trim, they can very easily and repeatedly recreate it.

00:11:15:03 - 00:11:18:13

Stephanie Hendrixson

They have a name for those files. They call them the Golden Build file.

00:11:18:13 - 00:11:37:05

Rohan Buntval

Once the build strategy and slice files are finalized and the build object then goes through a review and release process and this freezes the built object within our PLM system to make sure that it cannot be edited or cannot be changed by anyone unless it goes through another revision process.

00:11:37:05 - 00:11:58:20

Rohan Buntval

We differentiate our standard productionized build within our PLM system by giving it a little golden icon and we call it a golden build. So the production team will look for the golden build associated with the VRT part order that comes in and they will grab the slice file from that golden built object and send it to the printer.

00:11:58:22 - 00:12:01:05

Rohan Buntval

And that maintains consistency and

00:12:01:05 - 00:12:04:02

Rohan Buntval

minimizes the number of deviations that you might have in the process.

00:12:04:02 - 00:12:27:11

Pete Zelinski

So the golden build file. I love that. Not every file is golden because the team at this facility, they're doing development, there are new processes being proven out. But every time a production build is performed successfully, the recipe for that success is captured in one of these golden files.

00:12:27:11 - 00:12:29:15

Pete Zelinski

And it's not just how to produce a part

00:12:29:15 - 00:12:39:10

Pete Zelinski

whenever a combination of parts, a particular build set up, whenever that's performed successfully, that becomes a golden file. And then a very different combination,

00:12:39:11 - 00:12:42:21

Pete Zelinski

when that's performed successfully, that's another golden file.

00:12:42:21 - 00:12:58:20

Pete Zelinski

And this is the way that Baker Hughes is capturing the library of knowledge building up that library. This is the way they are achieving their short lead time, very responsive, high mix production process.

00:12:58:20 - 00:12:59:16

Mikhail Anisimov

So we've produced

00:12:59:16 - 00:13:01:14

Mikhail Anisimov

more than 70 VRT’s

00:13:01:14 - 00:13:05:09

Mikhail Anisimov

to date from more than 20 unique designs

00:13:05:09 - 00:13:07:23

Mikhail Anisimov

which is now part of a large

00:13:07:23 - 00:13:09:12

Mikhail Anisimov

AM digital inventory.

00:13:09:12 - 00:13:18:19

Rebecca O'Donnell

We see about a 70% reduction in lead time when it comes to 3D printing versus a traditional manufacturing method.

00:13:18:19 - 00:13:34:08

Rebecca O'Donnell

And this is really, this is a positive thing for us because it reduces the lead time that we have normally had to use when one of these has been specified either in a new valve or as a spare part.

00:13:34:10 - 00:13:37:11

Rebecca O'Donnell

So we can get the part to the customer quickly.

00:13:37:11 - 00:13:44:21

Rohan Buntval

If it's an emergency job, we can turn around the VRT in as little as 2 to 3 weeks.

00:13:44:21 - 00:13:56:17

Rohan Buntval

For VRT’s that require design team work to work on the model, the engineering drawing, the build strategy. We've turned around VRT’s in as little as 5 to 6 weeks.

00:13:56:17 - 00:14:08:16

Stephanie Hendrixson

So from 24 weeks down to just maybe two or three, in the event of an emergency like setting aside all of the benefits of assembly consolidation and reducing the risk of multiple components coming together,

00:14:08:16 - 00:14:12:14

Stephanie Hendrixson

that time savings is a massive benefit for Baker Hughes and its customers.

00:14:12:14 - 00:14:16:16

Stephanie Hendrixson

It can be so much more responsive and flexible to what customers need.

00:14:16:16 - 00:14:18:07

Pete Zelinski

And look where that leaves them.

00:14:18:07 - 00:14:29:08

Pete Zelinski

All of the time improvement that they've won by simplifying manufacturing, by bringing it in-house. They've got that the lead time improvement from additive manufacturing, they're there.

00:14:29:10 - 00:14:41:21

Pete Zelinski

So now Baker Hughes is free to begin playing with the design, see what the new possibilities are because they're using additive manufacturing and there is no one they have to coordinate with

00:14:41:21 - 00:14:43:12

Stephanie Hendrixson

All right. I think we got this

00:14:43:12 - 00:14:44:16

Pete Zelinski

Take it away.

00:14:44:16 - 00:15:02:11

Stephanie Hendrixson

These are variable resistance trim stacks. These are components that go inside of valves to resist cavitation. They are produced by Baker Hughes, and these 3D printed versions are a replacement for the way that these components used to be made by assembling lots of different stacks of metal together and brazing them.

00:15:02:17 - 00:15:11:11

Stephanie Hendrixson

It was a process that had a lot of steps involved, a lot of suppliers, and it took a long time. Now they are able to 3D print each of these trim stacks together as one piece.

00:15:11:11 - 00:15:14:23

Pete Zelinski

there is some post-processing involved in making these components.

00:15:14:23 - 00:15:16:17

Pete Zelinski

But essentially

00:15:16:17 - 00:15:41:03

Pete Zelinski

these parts are now produced in one piece, in one build through additive manufacturing, actually produced multiple trim stacks per build in additive manufacturing. There is a lot of variation in the product line for these variable resistance trim stacks. For Baker Hughes, each valve project is essentially a custom build, but

00:15:41:03 - 00:15:45:19

Pete Zelinski

the Baker Hughes team is turning it into a repeatable production process.

00:15:45:19 - 00:15:48:06

Stephanie Hendrixson

now, the Baker Hughes has this system in place.

00:15:48:06 - 00:16:02:21

Stephanie Hendrixson

They can very reliably and pretty quickly recreate any of these trim stacks that they have developed for additive manufacturing. The real win here is lead time. These parts used to take 24 weeks to source on average, and now they can produce them in just a couple of weeks when they need to.

00:16:03:03 - 00:16:04:13

Pete Zelinski

If you enjoyed this episode,

00:16:04:13 - 00:16:27:10

Pete Zelinski

we have more from Baker Hughes about their production system, how it works. You heard from Rowan in this episode. Our all access subscribers get to hear him talk about more about the golden billed file and how a build file becomes golden. You can subscribe to all access to It's easy, It's free. TheCoolPartsShow.com/AllAccess.

00:16:27:15 - 00:16:29:13

Stephanie Hendrixson

And again, this is the winner of the

00:16:29:13 - 00:16:43:09

Stephanie Hendrixson

production category for The Cool Parts Showcase in 2023, we will have upcoming episodes about the winners in the other two categories bespoke and proof of concept. So make sure to subscribe to the show on YouTube to get notified about those episodes or again,

00:16:43:09 - 00:16:45:20

Stephanie Hendrixson

sign up for all access to be the first to know.

00:16:45:20 - 00:16:52:00

Pete Zelinski

If you have a cool part you want to share, maybe pitch it for a future episode, or even if you just like the show.

00:16:52:01 - 00:16:55:13

Pete Zelinski

Email us. CoolParts@AdditiveManufacturing.Media.

00:16:55:13 - 00:16:57:09

Stephanie Hendrixson

Thanks for watching.

00:16:57:09 - 00:17:20:16

Unknown

This episode is brought to you by Carpenter Additive. We're past the point of not knowing how to qualify metal 3D printed parts. We know, it's just that different end users of those parts have different qualification requirements. Additive manufacturing service providers have to navigate that. And Carpenter Additive has to think about that in tailoring powder management solutions.

00:17:20:16 - 00:17:26:06

William Herbert

Our customers typically will have, if they are a service provider, they will have a series of

00:17:26:06 - 00:17:42:19

William Herbert

end user customers who may be say OEMs in the aerospace world, and each of them has a fairly large team of engineers who've been doing this for decades or more and have developed all these standards, regulations, paperwork.

00:17:42:22 - 00:17:45:21

William Herbert

So it is certainly a challenge to

00:17:45:21 - 00:17:49:12

William Herbert

thread the needle between all of these different requirements

00:17:49:21 - 00:18:05:16

William Herbert

We start really high level. We walk on the shop floor, we ask them about their source to sink, How do you bring in the materials goods in, send that material to each of the systems. And then what we're really interested in is how do they reuse that material?

00:18:05:16 - 00:18:07:17

William Herbert

So what we do is called the value stream map.

00:18:07:17 - 00:18:20:10

William Herbert

Pretty often that leads to a series of things that were either overlooked or hadn't really boiled up to the surface yet in terms of things that are potential risks or potential challenges or inefficiencies that exist

00:18:20:10 - 00:18:32:14

William Herbert

A lot of the customers we work with, especially in the more regulated industries such as space or medical or aerospace, have already been through those early learning stages. They've put five plus years into this.

00:18:32:16 - 00:18:37:06

William Herbert

They've done the product design and the design for additive manufacturing.

00:18:37:06 - 00:18:48:18

William Herbert

And now they're starting to reach some of the more finicky problems that you get when you're at the scale of maybe five, ten machines. You're running different materials simultaneously, you're doing different programs.

00:18:48:18 - 00:19:04:19

William Herbert

We get to take the best from the medical field and the aerospace field. We understand the specifications and the standards that exist in each of those fields, and we can sort of take the best elements of those and customize that to our customers.

Related Content

How Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreRead Next

Additive Manufacturing Versus Cavitation

The design freedom possible with laser powder bed fusion (LPBF) metal 3D printing is making it faster and easier to produce complex anticavitation devices for valves.

Read More3D Printing for Supply Chain Resiliency: AM Radio #39

Additive manufacturing can speed, strengthen and simplify industrial supply chains. How close are we to realizing this promise? Dr. Tim Simpson and Peter Zelinski discuss lead time, logistics and other factors on AM Radio.

Read More3D Printed Valve Part Protects Pipes by Preventing Cavitation: The Cool Parts Show #56

The Fisher Cavitrol Hex trim from Emerson divides the fluid flow into numerous parallel streams thanks to geometry made possible through additive manufacturing.

Read More

.jpg;width=70;height=70;mode=crop)