Vat Photopolymerization and VOC Emissions: Study Results and User Guidelines

New research conducted by Chemical Insights, part of Underwriters Laboratories, is studying volatile organic compounds (VOCs) and particles emitted by resin-style 3D printers. Here are what the results indicate and how to operate machines safely.

It’s usually the smell that captures a user’s attention first, whether the scent of heated plastic in a fused filament fabrication (FFF) 3D printer or the odor of liquid resin pouring into a build reservoir for vat photopolymerization.

“Once there’s an odor, you’ve already been exposed,” says Dr. Marilyn Black, vice president and senior technical advisor at Chemical Insights Research Institute, a not-for-profit institute of Underwriters Laboratories dedicated to studying the health risks of emerging technologies. For the last few years, part of this work has centered around 3D printing, especially as it is being applied in non- or semi-industrial environments such as maker spaces, schools, libraries, homes and offices.

Odors from 3D printing are the result of chemicals released during the process, and the reason this work was undertaken in the first place: New 3D printing users noticing the smell, and sometimes experiencing a physical reaction such as irritation, started to wonder about the safety of these devices. People began to reach out to Chemical Insights for more information. Were the 3D printers safe? What was the smell, exactly, and how could users deal with it?

Finding existing data lacking and hard to compare, Black and her team have developed a scientific testing protocol for evaluating 3D printers, beginning with extrusion-style FFF models. Printer manufacturers, material suppliers, users and others collaborated with Chemical Insights to facilitate this research, helping to build a 3D printer and filament database and establish acceptable levels of chemical and particle emissions. That work has resulted in a new standard for testing and assessing these 3D printers under ANSI UL 2904; it is now possible to purchase “low toxicity” systems that have been certified to this standard.

Now, Chemical Insights has turned its attention to another polymer 3D printing technology increasingly popular in these liminal spaces: vat photopolymerization. A new study recently published contains the details from the first tests of one of these systems, including the 3D printing, cleaning and curing steps.

FFF Versus Photopolymerization Emissions

The testing setup at Chemical Insights. Sensors inside this chamber capture information about the substances and particles emitted during 3D printing and related processes. All images courtesy Chemical Insights.

The testing protocol for a 3D printer at Chemical Insights involves placing the system in an exposure chamber, essentially a room-sized stainless steel box that simulates the airflow of a typical school or office environment, with the exception that the air inside is extremely clean. As the 3D printer runs inside this chamber, instruments collect data about the chemicals emitted, particles detected and particle size distribution.

When fused filament fabrication 3D printers are tested this way, they tend to emit a limited number of chemicals (highly dependent on the filament material used) and a fairly high quantity of particles, many of which are ultrafine particles that can be easily inhaled and carry volatile organic compounds (VOCs) deep into the respiratory system. When the vat photopolymerization printer was tested, the stereolithography system produced a greater variety of VOCs than extrusion-style 3D printers but far less particulate and hardly any ultrafine particles.

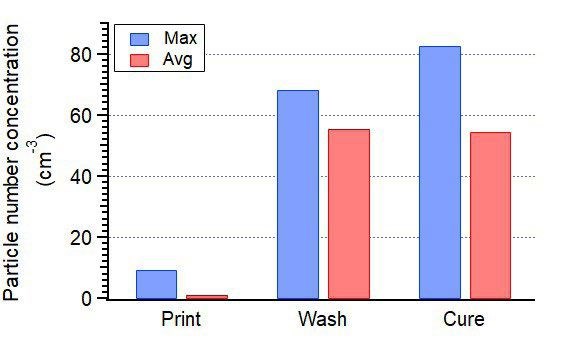

The maximum particle number concentration was below 100 per cm3 for all steps of the vat photopolymerization process. FFF 3D printers in the same conditions emitted higher levels of particles, in the range of 103-105 per cm3.

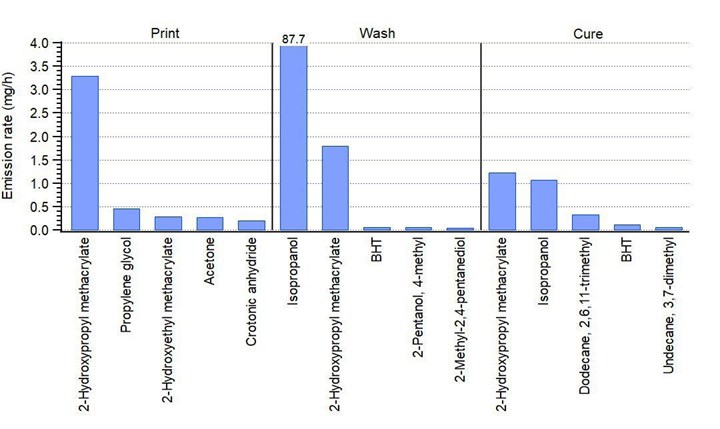

“That’s what you might expect from a wet system, where you’re printing with a liquid photopolymer versus a dry filament,” Black says of the reduced particle emissions. The greater area of concern with a photopolymerization-style printer lies in the variety and amounts of chemicals emitted in the printing process, but also during the cleaning cycle (which often includes an isopropyl alcohol-based washing fluid), and during the UV curing of the parts.

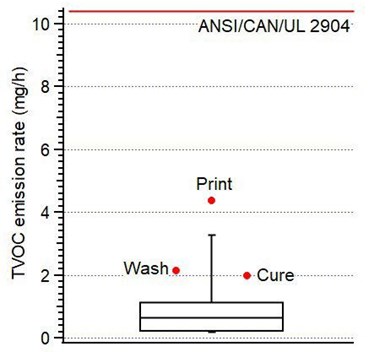

The total VOC emissions detected in this study are marked with red dots, while the boxplot indicates VOCs detected in the FFF research. In both cases, rates are below the maximum allowable level in ANSI/CAN/UL 2904 (the red line).

The study detected 40 different VOCs during the printing cycle, 34 during the wash cycle, and 42 during curing. This number of chemicals is between three and four times higher than what was observed from FFF 3D printing. The substances detected included known carcinogens such as formaldehyde and acetaldehyde, though in quantities below established health hazard levels. Of perhaps greater concern are other substances such as acrylates, which can function as sensitizers. Early contact with these chemicals may not cause any negative effects, Black explains, but repeated exposure can lead to a sensitivity akin to an allergic reaction.

“Once you become sensitized, it’s a chronic condition,” she says. “It never goes away.”

While many of these chemicals are present in quantities below thresholds that are considered safe in other contexts, Black points out that not much is known about these substances in combination with each other. The effects of this “chemical cocktail” on humans who come into contact with it is something that merits further research and concern.

Each step in the vat photopolymerization process emitted 34 to 42 distinct chemicals, far more than were observed in FFF 3D printing. The emission rates for the top five most-emitted substances during printing, washing and curing are shown here. The amounts alone are less concerning than the possible effects of the mixture of these substances.

Initial Guidance on Photopolymerization Safety

The study of photopolymerization printers is still in its early phases, and more systems will need to be tested and documented to better understand particulate and chemical emissions. New findings will be incorporated into the standard already established with FFF 3D printing. As data is gathered, Chemical Insights will be able to build out modeling tools that can simulate the behavior of 3D printers inside of various spaces to help new users set up spaces appropriately.

Although the study is ongoing, these early findings already suggest that many of the precautions applicable to FFF 3D printing can also be used to remove VOCs from vat photopolymerization environments:

- Hardware solutions. A direct exhaust system is the best-case scenario for removing and dissipating these chemicals, and Black also encourages filtering with HEPA and/or charcoal filters to eliminate them from the environment.

- Printer placement. Open areas with good air circulation tend to be best for dissipating any emissions. For home 3D printing situations, Black recommends placing the 3D printer near a window that can be opened during operation and avoiding “dead zones” with little airflow such as closets.

- Material tuning. As has happened with filament providers, Black expects that resin suppliers will be willing to tune their material formulations to reduce potentially harmful VOCs. Cleaning solutions for resin-based parts could also be another area for formulation tweaks.

- Training. Finally, educating users about the equipment they are buying and how to use it safely is a critical line of defense against potential health hazards.

This last point — education — is especially critical for the small desktop 3D printers typically operated outside of industrial settings. In industry, Black notes, there is OSHA oversight about air quality in working conditions. No such protection or guidance exists in private homes or non-industrial settings, so it becomes increasingly important for her organization to not only research and gather data, but to disseminate information in an easily digestible format that educates non-industrial 3D printing users without frightening them.

(It might seem strange, then, to see this research reported in a publication dedicated to industrial 3D printing. But at Additive Manufacturing Media, we are seeing that the next wave of manufacturing enabled by 3D printing is coming at least in part from these liminal spaces, often driven by founders from outside the manufacturing world. We have already seen it happen, with businesses launched by frustrated parents, law students, industrial designers, architects, hobbyists, civil engineers, interior designers and more. When 3D printing enables democratized, accessible production, new people can enter into manufacturing in new, non-traditional locations. Some of the people making that leap are reading now.)

Ongoing experiments with additional vat photopolymerization materials and 3D printer brands will add to the dataset and create better understanding of the 3D printing process through modeling, complementing other continuing efforts. Chemical Insights’ previous FFF work is also now being expanded through toxicity research that looks at the effects of emissions on human biological systems. And additional 3D printing processes will be studied as well in the future, including systems for 3D printing with metals.

Related Content

3MF File Format for Additive Manufacturing: More Than Geometry

The file format offers a less data-intensive way of recording part geometry, as well as details about build preparation, material, process and more.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreThe New Misperceptions Of AM: AM Radio #35

Tim Simpson and Peter Zelinski discuss a way additive manufacturing has advanced: The misperceptions have shifted. Knowledge of AM among manufacturers is more sophisticated now. The concerns that inform the perceptions of newcomers have therefore changed.

Read MoreRead Next

Are Emissions from 3D Printing Hazardous to Your Health?

And if so, what can you do about it? NIOSH researchers share the organization’s approach to eliminate, avoid and reduce operator contact with volatile organic compounds (VOCs) and ultrafine particles from fused filament fabrication (FFF) 3D printers.

Read MoreAdditive Manufacturing Is Changing the Rules on Safety

Bringing safety to the forefront helps to mitigate the risk of additive technology within a manufacturing environment.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More

.jpg;width=70;height=70;mode=crop)