Additive Manufacturing Standards

There are gaps in additive manufacturing where no published standard or specification currently exists for AM to respond to a particular industry need. Learn about the resources and additive standards and make more sense of the growing technology in this sphere.

There are gaps in Additive Manufacturing where no published standard or specification currently exists for AM to respond to a particular industry need.

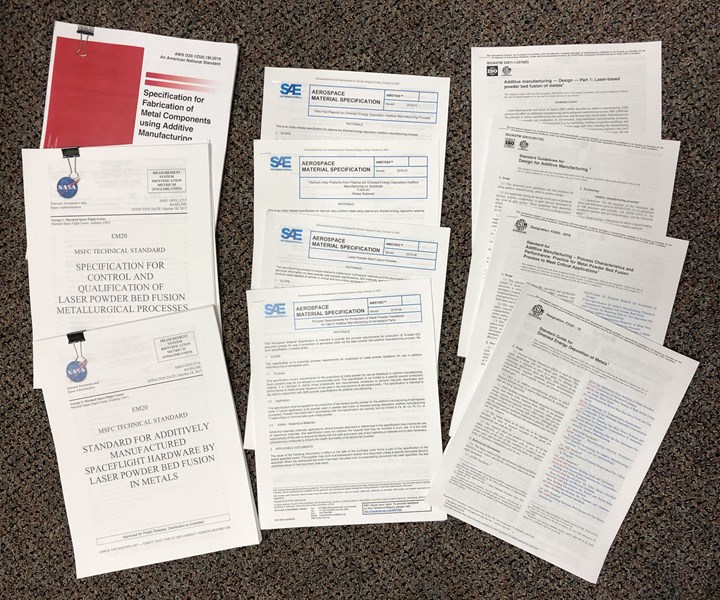

While seven processes may not seem like much to learn, the subtle variations of each additive manufacturing (AM) process and the hundreds of systems available in the market make AM a challenging technology to stay on top of. New entrants and rapidly improving technologies make buying decisions even more difficult, and it makes it even more challenging for standards to keep pace. As if that weren’t bad enough, America Makes, the National Additive Manufacturing Innovation Institute, in coordination with the American National Standards Institute (ANSI), identified 93 gaps where no published standard or specification currently exists for AM to respond to a particular industry need (e.g., how to characterize the spreadability of powder feedstocks used in powder bed fusion processes).

On the bright side, things are much better now than when I started writing this column three years ago. This month I thought I would highlight a few resources and standards for those struggling to make heads or tails of all of the AM processes that I have been discussing.

First off, you need to make sure that you are using the right terminology. If you are uncertain about some of the process definitions or key terms, then ISO/ASTM52900-15 is the place to start. This standard defines basic nomenclature, important terminology, and commonly used acronyms in the industry. This standard supersedes ASTM F2792-12a, which was withdrawn once the joint ISO/ASTM standard was developed and published in 2015.

Of the seven AM processes, powder bed fusion (PBF) and directed energy deposition (DED) are seeing the most activity in terms of standards development. These two AM processes enable the production of metal end-use parts, which ultimately need to meet the same requirements as any traditionally made component. As such, companies are clamoring the loudest for standards for PBF and DED to ensure that their processes and parts can be qualified and certified accordingly.

Last year, SAE International released an Aerospace Material Specification (AMS) for laser PBF (AMS7003), and ASTM International released a standard to characterize the performance of PBF processes for producing metal parts serving critical applications (ASTM F3303-2018). Meanwhile, ASTM International issued a standard guided for DED with metals in 2016 (ASTM F3187-16), and SAE International is actively developing standards for specific DED processes (e.g., AMS7005 defines specifications for wire fed plasma arc DED) and materials made via DED (e.g., stress relieved Ti-6Al-4V parts made with plasma arc DED is governed by AMS7003). Both of these standards were just released in 2019.

If you are looking for more general guidance on metal AM, or haven’t decided yet on PBF or a specific type of DED, then the American Welding Society (AWS) specification for fabrication of metal components using AM is a good place to start (AWS D20.1/D20.1M:2019). The AWS specification provides process flowcharts for both PBF and DED for components with different levels of criticality. They also provide sample records for test builds and qualification builds for processes and parts. They are also one of the few standards to outline guidelines for qualifying the performance of machine operators and inspection personnel, leveraging their related experience qualifying training for operators and inspectors in the welding industry.

On the design side, ISO and ASTM International have been actively collaborating on new AM standards. General guidelines for design for AM were released in 2017 (see ISO/ASTM 52910:2017(E)), and specific design guidance for laser-based PBF is now available for both metals (see ISO/ASTM 52911-1:2019(E)) and polymers (see ISO/ASTM 52911-2:2019(E)). Meanwhile, if you are wondering how to dimension and specify tolerances on lattice structures and complex shapes that can be made with AM, then ASME’s standard for product definition with AM is the best place to start (ASME Y14.46-2017). The original version is currently being reviewed for updates and will be re-released as soon as balloting ends.

In terms of materials, powder characterization is important to specify the right feedstock for a PBF or powder-fed DED system. The ASTM Standard Guide for Characterizing Properties for Metal Powders used for AM processes provides relevant guidance (ASTM F3049-14). It also references several complementary standards from the Metal Powder Industries Foundation (MPIF), which just released a new collection of powder characterization methods for metal AM processes. Meanwhile, wire feedstock for DED is being governed by existing AWS specifications for the welding industry since the same feedstocks are often used on wire-fed DED systems. The A5 Committee of AWS issues standards and guidance on filler metals, consumables, etc. (e.g., AWS A5.01M/A5.01: 2013), and more information can be found on the committee’s website.

While standards are advancing for AM, databases of material properties and design allowables are lagging. Qualified databases of materials are becoming available for popular polymers like ULTEM 9805 thanks to the efforts of rp+m and America Makes, but comparable efforts for metals are still underway. It will likely be awhile before this data is publicly available given the time and cost to generate this information for metals used in AM.

Despite the lack of material databases, guidance documents are available for heavily regulated industries (e.g., medical, aerospace). The FDA released a guidance document in 2016 for medical devices being made with AM. The FAA is actively developing a strategic roadmap for AM process qualification and part certification for aerospace applications. For spaceflight hardware, NASA has released a standard for metal components made with laser PBF as well as a specification for qualification and control of laser PBF processes for metals. These are useful documents that other industries are actively evaluating for adoption. Finally, ASME has launched a special joint committee to evaluate the use of AM for pressure technology (e.g., boilers, pressure vessels) and regulation within nuclear codes and standards.

If this is still too daunting, then the best place to start is the America Makes and ANSI Additive Manufacturing Standards Collaborative (AMSC). Their standardization roadmap is over 260 pages long; so, you may want to start with the standards landscape document, which is 20 pages. As for those 93 AM standard gaps, their website added an interactive portal in October 2019 to help track standard development. I have been using it some this past week, and I have been impressed with the website’s simple layout and level of detail provided for each of the standard gaps identified by the committee.

Related Content

How to Organize for Additive Production: AM Radio #42

Tim Simpson and Peter Zelinski discuss the next steps for succeeding with AM: After technical and process successes come the cultural, organizational and even costing considerations associated with this mode of manufacturing.

Read MoreImplicit Modeling for Additive Manufacturing

Some software tools now use this modeling strategy as opposed to explicit methods of representing geometry. Here’s how it works, and why it matters for additive manufacturing.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read MoreRead Next

Wire Arc Additive Manufacturing Delivers Low Buy-To-Fly Ratios

Manufacturers in the aerospace industry buy expensive raw material with one common goal: to make it fly. To reduce its buy-to-fly ratio (the ratio of material inputs to final part output), this company turned to wire arc additive manufacturing to create near-net shape parts.

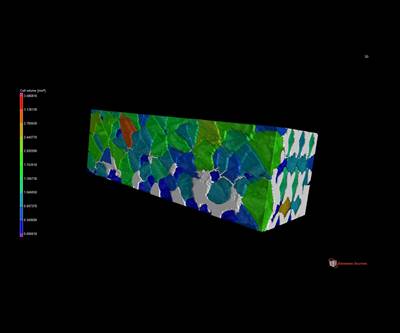

Read MoreCT Scanning Reveals What Isn’t There in 3D Printed Parts

3D Engineering Solutions offers CT scanning as a powerful nondestructive testing (NDT) solution for inspection. For 3D printed parts, sometimes revealing the space inside can be just as valuable as mapping what was printed.

Read MoreInside the Penn State Additive Manufacturing Master’s Program, Part 1

PSU's engineering master's degree in additive manufacturing and design offers students and manufacturing professionals a higher education in a continuously maturing field.

Read More

.jpg;maxWidth=150;quality=70)

.jpg;maxWidth=400;quality=70)