Stainless Steel Pelton Runner Created with 3D-Printed Molds and Cores

A manufacturer in India reduced lead time and increased efficiency in delivering castings using sand 3D printing from Voxeljet to create tooling.

Just a few years ago, Kirloskar Brothers Limited (KBL) would have needed a couple of months to deliver a 3,200-kg Pelton runner like the one pictured above. However, thanks to 3D printing technology from Voxeljet, KBL can now deliver these castings in a matter of weeks. Sand tooling manufactured with Voxeljet’s 3D printing equipment enables the company to create cores and cavities more quickly, reducing the lead time on its metal castings.

KBL serves water and power infrastructure projects by supplying parts for industrial and agricultural pumps, industrial valves, engines, and water runners. The company has eight production facilities in India as well as locations in Egypt, South Africa, Thailand, the Netherlands, the United Arab Emirates, Great Britain and the United States.

KBL’s main challenge is meeting extremely short timelines for parts with complicated geometries that require high accuracy and repeatability, such as spare parts. Conventional patterns and core boxes can take months to manufacture. Additionally, it is difficult to maintain the integrity of critical geometries with these traditional processes, which limits efficiency.

To design more flexible, efficient products, save time, and optimize its manufacturing process in a sustainable way, KBL decided to look for alternative manufacturing methods and settled on 3D printing. Using this technology, sand casting molds and cores can be produced quickly, on-demand and cost effectively. The Voxeljet’s VX4000 system, with a work envelope measuring 4,000 × 2,000 × 1,000 mm, was a ready match for the dimensions of the sand molds required by KBL.

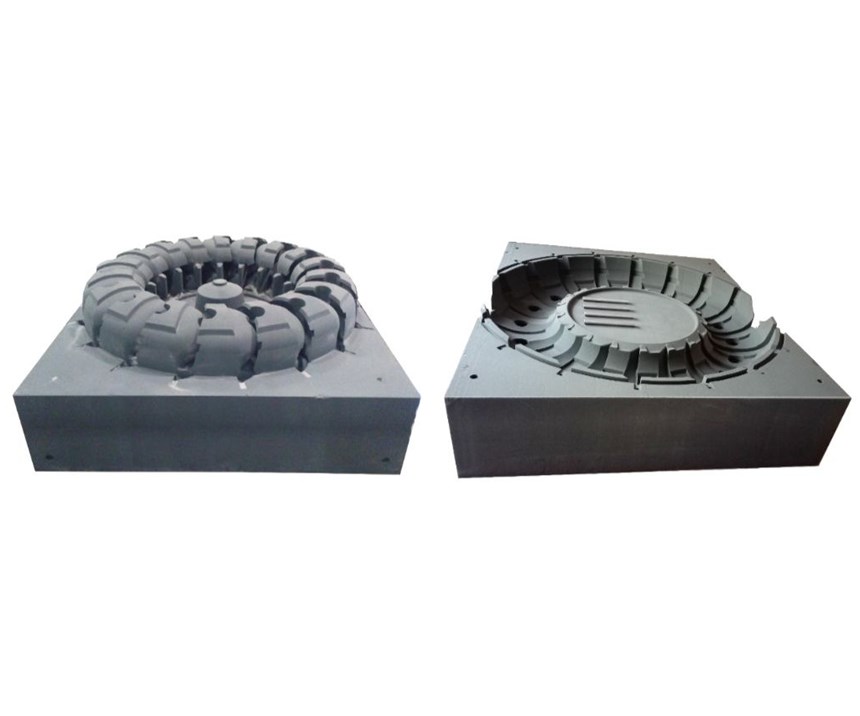

Manufacturing the Pelton runner pictured above required a mold set comprised of cope, drag and 18 bucket cores, a total of 5,700 kg of silica sand and furan binder. Using the Voxeljet system, KBL manufactured all the required tools within 72 hours. No postprocessing was required except for the application of a proprietary coating before the mold was ready for assembly and casting.

KBL cast the final 2,000-mm-diameter, 3,200-kg Pelton runner in this mold from CA6NM stainless steel, with a yield of 56 percent.

“We use 3D-printed molds for all castings that require close dimensional accuracy, very short lead times or simply small batch sizes.”

“Thanks to 3D printing, we have reduced our delivery times drastically,” says Ravi Birajdar, vice president and head of corporate research engineering and development at KBL. “Conventional production of critical molds and cores would usually take months. Now, we have molds ready for casting in just a couple of days. We use 3D-printed molds for all castings that require close dimensional accuracy, very short lead times or simply small batch sizes. At KBL we are also very happy to achieve repeatability and better surface finishes with 3D-printed molds.”

In addition to Pelton runners, KBL is now using sand 3D printing to make integral cores of impellers, bowls and Francis runners, which the company says are very challenging to achieve with conventional core boxes.

Related Content

-

How AM Enables Cobot Automation for Thyssenkrupp Bilstein (Includes Video)

The shock absorber maker has responded to its staffing shortages through extensive use of collaborative robots. In-house 3D printing makes this possible by providing the related hardware needed to complete the cobot-automated cells.

-

Video: 3D Printed Hand Tools in Action on Pella Corporation Factory Tour

Examples include an invention for quickly installing window and door weather stripping, a fitting for giving the proper angle to a nail gun, and a clip for which the color is an important feature.

-

Ice 3D Printing of Sacrificial Structures as Small as Blood Vessels

Using water for sacrificial tooling, Carnegie Mellon researchers have created a microscale method for 3D printing intricate structures small enough to create vasculature in artificial tissue. The biomedical research potentially has implications for other microscale and microfluidics applications.

.jpg;width=70;height=70;mode=crop)