Additive Manufacturing and CNC Machining Enable Driver Clubhead with Increased Performance

A combination of laser sintering, advanced materials and CNC machining enabled the creation of the KD-1 high-performance golf driver clubhead.

Share

Read Next

The engineering of new golf clubheads takes place within a restrictive box. The USGA and R&A (Rules Committee for Professional Golf) have placed limitations on the maximum size and volume that a golf driver can be, meaning that major golf club manufacturers tend to produce products that are very similar to one another. Engineering a high-performance golf driver within these parameters means that new designs typically focus on reducing cost and increasing output through well-established strategies—optimizing the thickness of each surface, controlling the total weight and tuning the center of gravity of the assembly.

In addition to the constraints placed on club design by golf’s governing bodies, the technologies traditionally used to produce clubheads are also restrictive. Relying on tooling for casting and forging is labor-intensive and expensive, limiting the geometry that can be produced and tending to preclude small runs or customized parts. In addition, casting and forging have wide tolerances plus part-to-part variations, requiring secondary operations.

To address these limitations, Krone Golf recently worked with CRP Meccanica and CRP Technology (both part of the Italy-based CRP Group) to develop a driver club head that would 1) help break out of traditional "mass produced" manufacturing techniques and lay the groundwork for mass customization and 2) offer improved quality and performance. To achieve these goals, the companies combined additive manufacturing with CNC machining of advanced materials.

Krone and the two CRP companies created a new composite driver clubhead made from multiple materials, each chosen for a specific function. By combining processes, the team created a production solution that would enable small runs and customization via additive manufacturing while solving problems of speed and accuracy through the integration of machining. The clubhead, known as the KD-1, complies with the necessary weight and size constraints while also offering improved performance for the user.

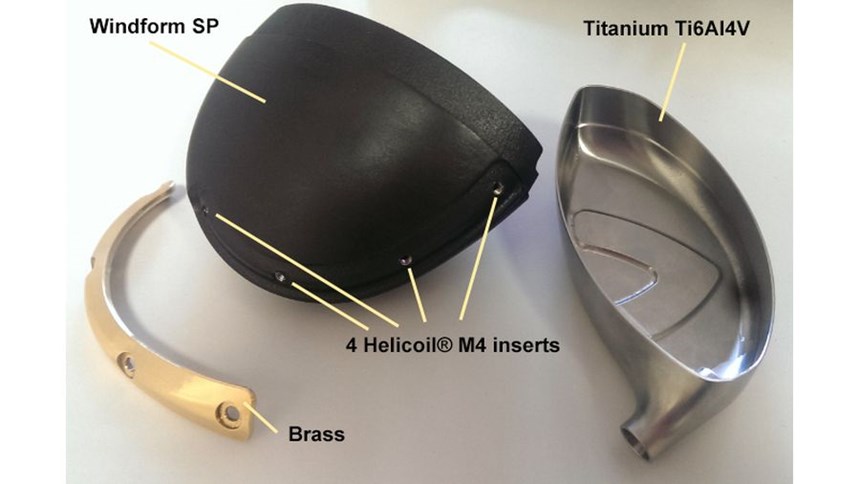

The KD-1 clubhead consists of a body, a face (the striking surface), a hosel (the socket into which the club's shaft fits) and a weight. The body is additively manufactured via laser sintering from Windform SP, a carbon-filled additive manufacturing material. It is highly ductile with good mechanical resistance, and can tolerate high stress fatigue including vibration and shock without the risk of breaking because its elasticity helps to absorb these stresses. The additive manufacturing department at CRP Technology performed the SLS process. The clubhead body also includes four Helicoil M4 inserts used to fasten the weight.

Both the face and the hosel of the club are CNC machined from solid titanium. Thus, each component, whether 3D printed or machined, is formed in a single operation. The alloy used for the machined parts, Ti6Al4V, is lightweight but durable. Following machining, the face is sand-blasted to clean its external surfaces. Finally, the weight of the clubhead is CNC machined in brass from solid, and sand-blasted as well. CRP Meccanica performed the machining and sand-blasting of these parts.

The three companies saw several advantages in this combination of CNC and additive processes. Both operations are lean and direct; once the CAD file is verified, and programming and setup are complete, the part can be made directly using CNC or SLS equipment that can run virtually 24 hours per day. Compared to designing and producing a tool for molding, additive manufacturing gives engineers more flexibility in the timeline to make design improvements.

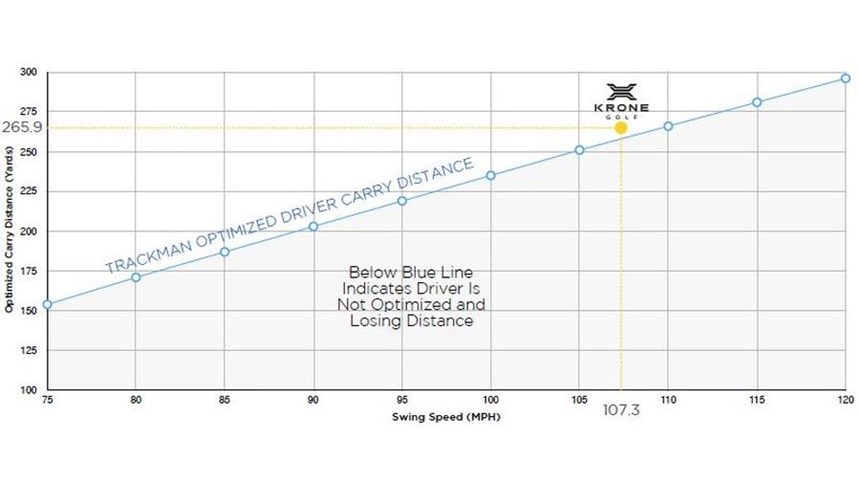

Meanwhile, for the golfer, the resulting clubhead offers performance improvements over other heads. In fact, the clubhead has out-performed the theoretical limits for the club predicted by Trackman, the golf industry standard for measuring distance and club performance. In testing, the clubhead achieved a carry distance of 265.9 yards at a swing speed of 107.3 mph, above the Trackman limit (shown in Figure 4, above).

Krone Golf and the two CRP companies say that they plan to continue working together to refine the design, and that they will work toward the concept of mass customization for golf components.

Related Content

3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreRead Next

Alquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More

.jpg;width=70;height=70;mode=crop)