Additive for Fixturing, Machine Tool Components

Additive manufacturing is being used for more than prototyping these days. Here are two examples of how a machine shop might leverage this technology.

A little while back, I visited 3D Platform (3DP) to learn more about the company and its affordable Workbench line of open, large-format 3D printers. Born from PCB Linear, manufacturer of linear motion components actuators and motors, 3DP offer its Workbench 3D printer with a build volume of 1 meter × 1 meter × 0.5 meter. The machine’s SurePrint servo technology enables print layer resolution a low as 70 microns for a range of materials including ABS, Nylon and others. Plus, a folding gantry enables the machine to fit through a standard door.

This machine can be used for a variety of applications for printing prototypes, production parts, artwork and sculptures, and personalized items commonly derived from 3D scans often used in the medical, fashion, education and entertainment industries. That said, machine shops can also use it to print jigs, fixtures and other components. In fact, 3DP has done that for its own in-house production needs.

For example, the company printed a profile rail wiper for one of its machine tools (see the second photo in the slideshow above). Although that machine has a built-in rail surface wiper that pushes big steel chips off the rail surfaces, the wiper failed to catch smaller pieces that can be caught in between the rail and the ball bearing system, causing the ball bearing system to fail prematurely. The printed rail wiper added to the machine keeps small chips off the rail while helping retain oil and lubrication in the rail bearings.

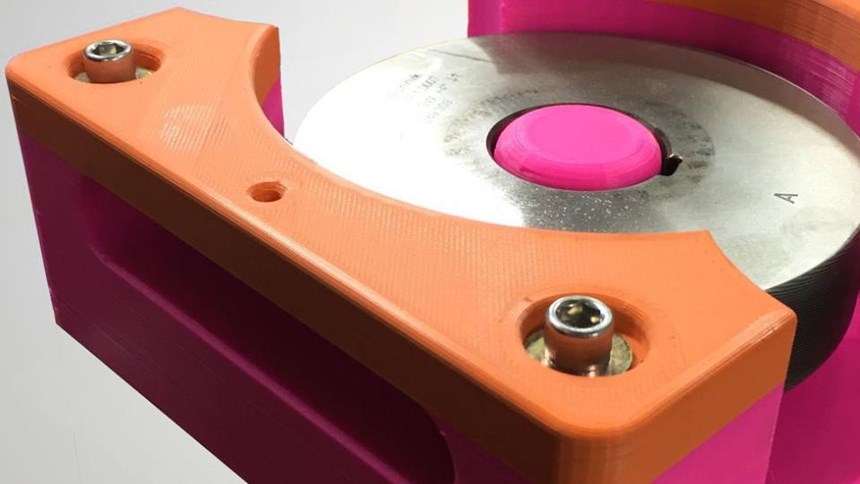

In addition, 3DP printed a thread rolling machine die holder (see the third photo) that stores the entire set of thread rolling instruments conveniently in one place, supporting the company’s 5S workplace organization efforts.

Click on the "Tooling" button below for a collection of articles describing similar ideas for 3D printing of tooling, fixtures, jigs and related items for use in a machine shop.

Related Content

-

Complete Speaker Lineup Announced for the 3D Printing Workshop at NPE2024: The Plastics Show

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

-

4 Weeks from Design to Molded Part for Medical with Metal 3D Printed Tooling

Mold builder Westminster Tool applied the Trueshape process from Mantle to produce tooling to take a medical device from prototype mold to full-scale production in a matter of weeks.

-

4 Ways Augmented Reality and 3D Printing Intersect

Augmented reality (AR) is bringing benefits to additive manufacturing, and vice-versa.