AM I Navigator Initiative Helps Users Scale, Integrate Additive Manufacturing Into Traditional Production Workflows

The AM I Navigator initiative offers additive manufacturing users individual guidance with a comprehensive approach to navigate the complexity of the evolving landscape in industrial 3D printing.

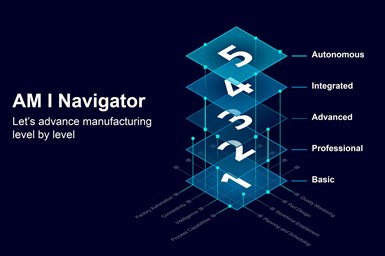

With the model, companies can refine their current status as well as their future target into 5 levels. Photo Credit: Siemens

Siemens, DyeMansion, HP, BASF Forward AM and EOS have created the Additive Manufacturing Industrialization Navigator (AM I Navigator) Initiative to help additive manufacturing (AM) users navigate through the complex landscape of AM. The initiative offers AM users individual guidance with a comprehensive approach to navigate the complexity of the evolving landscape in industrial 3D printing.

The group says its holistic maturity model defines the five stages of AM industrialization — reflecting the big picture of what it takes to adopt and realize AM applications for specific business cases.

The initiative is designed to help AM users determine the level of automation a company needs for its specific applications and business cases. It can be a long and complex road to evolve production through AM manufacturing. This requires different degrees of automation, connectivity, repeatability and quality, process know-how and material knowledge.

Recent developments along the entire 3D printing process chain promote the reproducibility, throughput and productivity of additive use cases — from material to final product. However, the applications only unfold their full potential if everything is aligned with the company’s actual business model.

But some pragmatists may doubt whether industry or its companies are ready for it yet. The AM I Navigator helps charts the course through the complexity in industrial 3D printing for companies with varying levels of industrialization in AM and different application requirements.

AM I Navigator — What's behind it?

The AM I Navigator Initiative’s holistic maturity model defines the stages of industrial 3D printing along the entire process chain from material to machines to automation. Moreover, creating a common understanding of the different stages helps AM users find ways to scale and integrate AM into traditional production workflows.

The factors for the respective stages come from different areas and include more than just production:

- A strategy setup composed of an AM strategy, applications and business cases

- Organizational structures and cultural maturity of employees

- Expertise, automation and connectivity along the entire value chain from design through production to quality, maintenance and service

Using AM I Navigator to Create Right Strategy for AM

The status quo of AM can be analyzed by applying a maturity check for each company following the structure of the AM I Navigator framework. The check is a structured approach that will show the current maturity level of AM and the potential for improvement for the company in question. The approach is based on the Siemens Digital Manufacturing Excellence learnings. Depending on the use case and business model, a company requires a different “maturity level” in AM. With the framework, AM users can refine their current status as well as their future target into five levels — from basic manual production to fully autonomous additive production.

Creating a common understanding of the different stages helps AM users find ways to scale and integrate AM into traditional production workflows.

Based on this structured approach, detailed recommendations are available for action on how production can be further developed in the respective company. According to the companies, it is particularly important the individual steps in the process chain are coordinated with each other. Only open and interoperable AM adds value to the entire production. Suitable action steps will lead to the individually desired target state, depending on the application and maturity level of the company. The results from the checks are made available to the respective company and may act as best practices to provide a detailed picture of the evolution of industrial 3D printing.

Additional AM technology providers worldwide are welcome to join the first wave pioneers to further shape the AM I Navigator initiative. The initiative is open to other thought leaders from all industries to build related offerings.

- Learn about the Farsoon partnership with Siemens to enhance the application of Siemens automation and drive solutions in Farsoon AM machines.

- Read about the Siemens Energy collaboration with Seurat to advance clean manufacturing. Seurat Technologies will develop 59 tons of additively manufactured metal components for Siemens Energy turbines.

Related Content

A Framework for Qualifying Additively Manufactured Parts

A framework developed by The Barnes Global Advisors illustrates considerations and steps for qualifying additively manufactured parts, using an example familiar to those in AM: the 3D printed bottle opener.

Read MoreLooking to Secure the Supply Chain for Castings? Don't Overlook 3D Printed Sand Cores and Molds

Concerns about casting lead times and costs have many OEMs looking to 3D print parts directly in metal. But don’t overlook the advantages of 3D printed sand cores and molds applied for conventional metal casting, says Humtown leader.

Read MoreThe Arrival of the AM Factory: How Proprietary Processes Deliver Production 3D Printing

Various recent articles report on companies using internally developed technology to equip factories and deliver on the promise of AM for production.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More