When Additive and Conventional Processes Work Together, the Result Is Manufacturing

Various recent articles demonstrate 3D printing and established processes finding one another and working together.

When executive editor Stephanie Hendrixson recently used a LinkedIn post to share some of her reporting on electroplating polymer 3D printed parts, one reader posted a comment in response that said, essentially: This is nothing new. Manufacturers have been electroplating plastic parts made via molding for some time.

Indeed they have. When I saw that post, and saw the comment, my thought was: Yes — and isn’t it great? Here is an area in which additive manufacturing does not have to chart a new course. AM can benefit from a processing step already well understood from parts made other ways. Not everything needs to be an invention.

And yet, as a possibility for 3D printed parts, electroplating is transformative. Stephanie explores why in an article on AM meeting electroplating at RePliForm. While 3D printing in plastic offers a quick, economical way to obtain a complex form, plating this form can then give the plastic part some metal properties. The combination connects metal to the design freedom of additive in a way that does not require the investment in 3D printing a fully metal part.

Meanwhile, the combination also stands as an example of a much wider phenomenon, indicative of a transformation that has already occurred. In the wake of additive manufacturing’s arrival and acceptance as an option for production, 3D printing and more established processes are increasingly finding one another, interacting, and living and working together.

The beginning of this interaction takes the form of providing alternate paths. Injection molding, for example, can move more nimbly if there is a way for 3D printing to deliver mold tooling quickly when conventional moldmaking’s lead time is too long. Daimler Trucks and the Oregon Manufacturing Innovation Center recently extended this idea to large injection molds, conducting a trial that demonstrated the effectiveness of large-format DED for creating large mold tooling in days instead of weeks.

Additive itself also benefits from having the near availability of an alternate path. One impediment to AM finding its best opportunities has been the need for potential users to see and recognize as much — that is, the need for potential users to be able to pre-identify and pre-qualify their application for additive, so they know to engage an AM provider. One major AM provider, Fathom, has now addressed this by making itself something much more. The company’s success as an AM specialist provided a starting point allowing it to branch out into now providing machining, molding and other processes. As a result, even as the possibilities for production AM continue to advance for Fathom (notably through a high-rate system from Evolve), the chance to serve a broad array of production work, and direct only the work to additive that makes the most sense for it, helps to assure that AM will be used in a way that realizes its full promise.

And what if, instead of alternate paths, there is a combined path to consider? 9T Labs leverages the strengths of 3D printing and molding together.

But then there is also a different kind of path to consider: the path of the part itself, the workflow. In metal AM in particular, 3D printing is practically never the end; downstream operations — conventional operations — must complete the part. And much of the cost of additive production is apt to be found here, not because these downstream steps are costly, but because the move from 3D printing to conventional processing is where labor enters the picture. Does this have to be the case?

Not at all. Transferring work automatically and repeatably from one precision value-adding machine to another is a problem that has been solved, and now the time has come to extend these solutions to AM. Or even to tailor new solutions. As another recent article shows, DMG MORI is demonstrating that the key to integrating laser powder bed fusion with CNC machining into a more automated workflow might lie with simply modifying the build plate to make it more friendly to chucking and a robot.

With this workflow integration, along with the close connection to plating as at RePliForm or molding as at 9T Labs, the interaction between new and established processes becomes close indeed. The result is additive manufacturing. We have long made this point: AM is more than 3D printing.

In a sense, though, the result is also something more general. The result is manufacturing, just that, as it has always been. Manufacturing has always consisted of choosing or combining processes for the strategy or sequence the part or product needs. As additive takes its place as an accepted process option for production, that acceptance will increasingly involve 3D printing simply finding different ways to figure into the mix.

Related Content

6 Considerations When Launching an Additive Startup

Recent additive manufacturing (AM) startup owner, JP Kinerk, shares his experience by offering helpful advice for others just starting out in the additive realm.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreUnited Performance Metals Is the One-Stop Build Plate Shop for Production AM

United Performance Metals (UPM) started producing build plates for metal 3D printing in 2019. Now, the company offers full refurbishment and inventory management for this critical additive supply — with more to come.

Read MoreAdditive Wins on Cost, Plus Process Monitoring and More from RAPID + TCT 2023: AM Radio #38

Additive manufacturing is finding success as a cost-effective manufacturing method. New options for process monitoring are now available. DED is getting more precise. 3D printed chairs! What we learned and observed at RAPID + TCT 2023.

Read MoreRead Next

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreAdditive Manufacturing's Evolving Role at Fathom Now Emphasizing Bridge Production

Bridge production is currently the biggest opportunity for additive manufacturing, says Fathom Manufacturing co-founder Rich Stump. How this service provider leverages AM while finding balance with other production capabilities.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

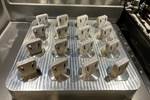

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read More