“Imagine every curb, every parking garage, every retaining wall is sucking carbon out of the environment,” says Zachary Mannheimer, founder and board chair of Alquist 3D. What these objects have in common — and the reason why they are not fulfilling this vision today — is that they are largely built from concrete. Rather than a carbon sink, concrete is a well-known creator of carbon by virtue of the energy consumption and CO2 emissions associated with its production. Nonetheless it is by many estimates the most common building material worldwide. Changing the construction industry’s reliance on concrete to produce buildings and infrastructure could go a long way toward changing humankind’s relationship with the planet — and Alquist 3D sees a pathway to get there.

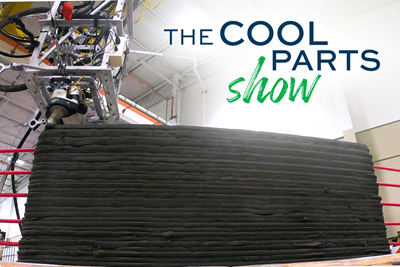

Alquist 3D developed a robotic 3D printer with RIC Technologies which places a Kuka robot on a trailer for easy mobility to job sites. The mixer in the background supplies the printhead with properly mixed geopolymer material for construction.

Or, perhaps more accurately, a system of coordinated efforts that can help drive construction along this pathway.

“We don’t want to be a construction company,” says Patrick Callahan, CEO. “What we really want to do is proliferate an ecosystem.”

For the Greeley, Colorado-based company that ecosystem has three pillars:

- 3D Printing Technology. Working with equipment supplier RIC Technology, Alquist 3D has developed a mobile robot 3D printing platform that can be deployed on job sites to 3D print homes and other structures directly.

- Products. At its Greeley headquarters, Alquist 3D is also developing capacity to manufacture infrastructure products — items such as benches, planters, curbs and more, which can be produced and shipped out from this facility. The company has plans to install tracks for robots that could travel between workzones, either 3D printing such products directly or extruding material into 3D printed molds.

- Licensing. Alquist 3D does not aspire to design and 3D print buildings directly; instead, it will license its mobile robotic 3D printing technology to contractors that can own and operate this solution within specific localities.

There is also another challenge to the future of construction that Alquist seeks to help solve: workforce. Along with its focus on 3D printing technology and products, the company is investing in creating a certificate curriculum together with Colorado’s Aims Community College that will provide students with training in 3D printing for construction, as well as the opportunity to intern with Alquist 3D for practical experience. (More than 100 students indicated interest in the first offering of the program, which kicked off August 5 with a full cohort of 20 enrolled students.) Altogether, the company aims to address the skills, hardware, software and materials that will change how things get built, and the roles that these structures can play.

Mya Rodriguez-Salas, field supervisor and former Alquist 3D intern, and Marco Hernández Ruiz, printer operator, prepare for a test print at the company’s Greeley headquarters.

Solutions for Mobile and Stationary Construction

Robotics and large-format additive manufacturing (LFAM) are key to Alquist 3D’s vision of greener buildings and infrastructure. For on-site construction, the company has developed a 3D printing solution with RIC that consists of a Kuka robot arm equipped with a printhead that is mounted on a trailer, and a material mixing station. Both pieces of equipment are compact, mobile and tuned to each other. The small-scale mixer is much smaller than a concrete truck or even the mortar mixer the company started out with — the more precise nature of 3D printing means that less material is needed at once. But the printer is designed for large-scale production; the robot sits on an elevated platform and has its printhead cantilevered away from the end of the arm for additional reach, enabling a printing Z height up to 20 feet tall.

The mixer used as part of the Alquist 3D system is small — 3D printing requires less material at once than a traditional concrete pour. But the precise moisture, feed rate and other parameters around the material must be carefully controlled in order to ensure proper curing and bonding of the geopolymer in printing.

The key to the 3D printing system is not really the robot, but the mixer and its handling of the build material. Geopolymer (more on this in a moment) has a tighter tolerance for moisture and must be dialed in for the specific location. A significant part of the innovation has revolved around sensor integration within the mixer and its pump (consistent pumping enables consistent printing) and developing appropriate “recipes” and software for controlling the material extrusion. Data about each batch of material is tracked so it can be analyzed and used to improve the system over time.

This is the system that licensees will implement to bring greener construction to their regions. Alquist 3D already has about 10 licensees in the pipeline with many of them coming online this year. The company sees its mobile solution as advantageous for construction projects including affordable housing because of its small footprint. Compared to in situ printers that rely on large gantries, the Alquist 3D solution is small, compact, and requires only a few hours to set up on site.

Meanwhile, 3D printing and robotics will also be applied in Greeley for Alquist 3D’s infrastructure products — many of which were commissioned by and will be proven out in the company’s hometown, as part of the city’s revitalization goals which prompted the company to locate here in the first place.

The company is currently developing a combination curb and gutter represented by this polymer prototype that will be implemented in Greeley.

Ryan Hasler, operations manager, describes a detail of this 3D printed PLA form that will be used to manufacture a planter design at the Greeley facility.

Some items like planters and benches will be 3D printed from geopolymer directly, using Kuka robots that will be installed on a track to serve many workzones at once. But others, like pavers and a combined curb-and-gutter system currently in development for the city of Greeley, will be made by casting geopolymer into 3D printed PLA molds.

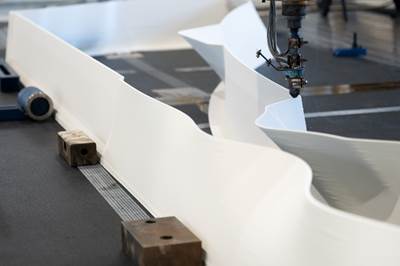

The company is using a large-format additive manufacturing machine from SynDaver3D (another Colorado company) with a 1-m3 print volume to develop and manufacture these molds. The same track-based Kuka robots will be used for this work as well, traveling between different molds to extrude just the right amount of geopolymer into each one for scale production of these products.

Infrastructure items such as benches and planters like this can also be 3D printed directly in geopolymer without a mold or form, enabling greater design freedom.

3D Printing with Geopolymers

About half of the company’s current facility is devoted to infrastructure products, while the rest is divided between R&D space for the mobile printer, and mixing and storage capacity for its geopolymer. Raw materials are stored in large bays at the back of the building, while the already-mixed material is held in an elevated silo, ready to be dispensed as needed.

Hasler points out how this test wall was used to prove out and refine printing parameters (the quality gets better the higher the layer) in conversation with Chris Vaugn, senior program manager, and me.

The geopolymer is a critical part not only of Alquist 3D’s printing technology, but also its carbon capture mission. The non-cementitious material is a mix of alumina silicate, fly ash, sand and proprietary additives that requires only about 7% water content to become printable (precise quantities depend primarily on the ambient temperature and humidity of the print location, and must be adjusted over the course of the build as conditions change). The material can incorporate industrial waste products, which makes it as much as one-third less expensive than concrete. Geopolymer also brings advantages to the 3D printing process and final structure.

“Our material takes well under half the time to cure compared to concrete,” Callahan says. “We’re talking hours versus days. We can layer and build faster because it sets quickly.”

Once cured the geopolymer is watertight, nonporous and offers good compressive strength. The material has withstood 8,000 psi in a 14-day pressure test, conducted using ASTM guidelines.

Benefits of 3D Printing for Construction

The company sees 3D printing as a way to reduce the number of workers needed on a job site (Alquist says to print housing in the field requires only a two-to-six-person crew with its mobile printer, mixer and material, depending on the size of the project), as well as a means of growing the construction workforce.

“3D printing is a gateway to attract young people back to the trades,” Mannheimer says.

As of yet, it is difficult to find crews capable of deploying 3D printing on a construction job site, which is why Alquist has invested so much in the curriculum program with Aims Community College. New means of construction require new programs for training those who will operate it.

Brent Imhoff, product manager, seen here overseeing the SynDaver Apogee 3D printer used for form work, is working on a curriculum with Aims Community College that will prepare students for work in construction 3D printing with courses in general 3D printing, robotics, materials, design and coding.

But workforce challenges aside, the company has already made strides in deploying its 3D printing technology. Alquist been involved in a number of construction projects including the Habitat for Humanity home pictured below, one of two produced in Williamsburg, Virginia, as well as a structure thought to be the world’s first 3D printed duplex, built in Hope Springs, Colorado. Other work underway includes on-site construction for the expansion of a commercial development in Tennessee; maritime applications such as oyster beds and reefs; and items for water management.

This Habitat for Humanity home in Virginia was 3D printed and completed in late 2023. More on this house. Source: Alquist 3D

The company believes its biggest impact is yet to come, however, and that it will be enabled by material science.

“The geopolymer is currently carbon neutral,” Callahan says, “and we’re aiming to make it carbon negative.”

Further R&D on the geopolymer formulation will be the key to realizing the dream of carbon capture rather than creation as the result of building and infrastructure projects. Recycled materials such as glass and plastic, and bio-based materials like hemp, could be future additions into the material to turn it from carbon-neutral into carbon sequestering, helping to mitigate the impact of decades of concrete-based construction.

Related Content

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreRead Next

3D Printed Prefab Homes, Made from Composite and UL-Certified

Mighty Buildings wants to change the construction industry with prefabricated houses 3D printed on demand from thermoset polymer composite. Two such buildings have already been installed.

Read More3D Printed Concrete Is Key to This Smart Wall: The Cool Parts Show #40

The SkyBAAM cable-driven 3D printer creates opportunities for embedded functionality in concrete, as demonstrated in this episode of The Cool Parts Show.

Read More3 Points About 3D Printing Large Parts We Can Learn From the Lunar Habitat (Video)

Ingersoll Machine Tools describes the capabilities and promise of large-scale additive manufacturing as seen in the 3D printed sections of the Rosenberg Space Habitat.

Read More

.jpg;width=70;height=70;mode=crop)