November/December 2020 Issue

November 2020

Digital Edition

Features

Featured articles from the November/December 2020 issue of Additive Manufacturing

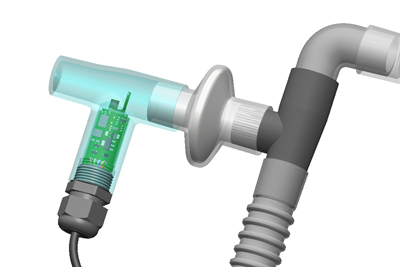

3D-Printed Molds Accelerate Substitute-Ventilator Validation

Fortify’s 3D printing and injection molding expertise saved Ventilator Project weeks and thousands of dollars as the nonprofit hurried to supply clinicians and hospitals at the start of the COVID-19 pandemic.

Read More

How a 3D-Printed Metal Ankle Implant Replaces an Entire Bone

Through a novel surgery involving a 3D-printed talus bone, surgeons at the University of Miami found success — and unexpected challenges — with a patient suffering from sickle cell disease.

Read More

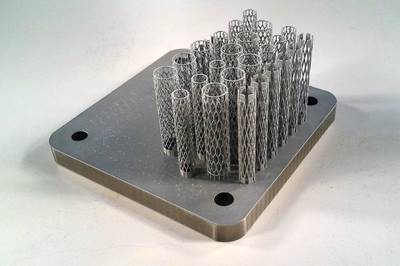

With This 3D Printed Block, EBM Is an Aid to CNC Machining

Holding the part is a challenge of machining for additive manufacturing. This medical manufacturer prints fixture tooling tailored to its additive parts.

Read More

Materials and Measurement Will Bring the Full Promise of AM — Implants Show This

Complex geometry plus short lead times are only the start of the wins additive manufacturing can achieve. Greater advance will come from material choices and customizing components, as 3D printed implants show.

Read More

3D Printed Ceramics Serve As Both Bone Graft and Support

Bioceramics including tricalcium phosphate and zirconia have been used to replace and stabilize human bone in reconstructive surgeries. Now, 3D printing brings customization and new design opportunities to these medical devices.

Read More

Workflow Is Key to Delivering Custom 3D Printed Implants for Animals

A veterinary study on the use of 3D printed titanium cranial plates for dogs has established a workflow for creating these custom devices in less than 3 weeks.

Read More

3D Printed Nitinol Opens New Possibilities for Arterial Stents

Researchers at Australia’s national science agency, CSIRO, have created the first self-expanding nitinol stents made via powder bed fusion. The project points to more opportunities with this shape memory alloy.

Read More

Can Microscale 3D Printing Reduce Surgeries for Glaucoma Sufferers?

Boston Micro Fabrication (BMF) is exploring this promise. Eye stents are made of metal today. Fine-detail additive manufacturing can enable polymer instead, improving patient experience.

Read More