Stratasys, CollPlant Unite Technologies for Industrial-Scale Bioprinting of Tissues, Organs

The joint development and commercialization agreement will initially focus on development of a bioprinting solution for CollPlant’s regenerative breast implants, addressing $2.6 billion market opportunity.

Share

Read Next

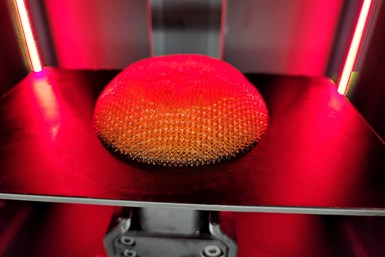

Stratasys and CollPlant Biotechnologies are collaborating on the development of a solution for bio-fabrication human tissues and organs using Stratasys’ P3 technology-based bioprinter and CollPlant’s rh-Collagen-based bioinks. The first project focuses on the development of an industrial-scale solution for CollPlant’s regenerative breast implants program.

Stratasys will provide its expertise in polymer 3D printing solutions for CollPlant, which is a regenerative and aesthetics medicine company developing technologies and products based on its plant-based collagen for tissue regeneration and organ manufacturing.

The bioprinter is based on Stratasys’ precise P3 3D printing technology in combination with CollPlant's flagship bioinks. The printer will enable the production of CollPlant’s breast implants, which are being designed to regenerate an individual’s natural breast tissue without eliciting immune response, providing a potentially revolutionary alternative for both aesthetic and reconstructive procedures.

Currently, the global breast implant market is estimated to be $2.6 billion, with breast reconstruction and augmentation procedures representing the second most common plastic surgery procedure performed worldwide. The most common breast augmentation or reconstruction procedures today are based on synthetic silicone breast implantations, which is an artificial substitution for natural regenerated tissue and has risks of complications.

As part of the collaboration, both companies have agreed to cross-promote each other’s bioprinting products. Stratasys’s bioprinter will be offered to customers together with CollPlant’s bioinks and, similarly, Stratasys’ bioprinter will be offered to CollPlant’s business partners and customers.

“Through this partnership with CollPlant, we have an important opportunity to transform health care with bioprinting to improve the lives of patients undergoing breast augmentation or reconstruction procedures,” says Stratasys CEO Dr. Yoav Zeif. “This agreement is well aligned with our strategy to deliver complete solutions for high-growth industry applications with our ecosystem of partners, and the production scale and precision 3D printing capabilities of Stratasys’ P3 Programmable Photopolymerization technology are a particularly strong fit for bioprinting applications.”

The partnership is focused on accelerating the industrialization of bioprinting for regenerative medicine. “Stratasys is leading in additive manufacturing and we are excited to collaborate ith them on this transformative initiative,” says Yehiel Tal, CollPlant CEO. “The P3 technology allows printing with high resolution and process control, and we believe that the combined, pioneering technologies of both companies will streamline the development and production process so that we have the most efficient means to produce our regenerative breast implants, and other potential tissues and organs. We believe that our rhCollagen-based regenerative implant has the potential to overcome the challenges of existing breast procedures that use silicone implants or autologous fat tissue transfer.”

In January 2023, CollPlant announced that it successfully completed a large-animal study for its 3D bioprinted regenerative breast implants. The preclinical study demonstrated progressive stages of tissue regeneration after three months, as highlighted by the formation of maturing connective tissue and neovascular networks within the implants, with no adverse events reported. Based on these positive results, CollPlant is planning to initiate a followup, large-animal study in the second half of 2023 using commercial-size implants to support subsequent human studies and future product commercialization.

- Read about the Stratasys partnership with Ricoh for print-on-demand medical models. This offering gives clinicians and patients increased access to patient-specific, 3D printed models for pre-operative surgical planning, diagnostic use and surgical education to improve clinical outcomes and drive significant savings through improved productivity.

- Learn how Stratasys’ innovation extends to moviemaking for 3D printed camera components used to capture “Avatar: The Way of Water” film. SNL Creative used AM materials from Stratasys and other providers to create stereoscopic camera rigs used by the production team during the creation of the new Avatar film. The custom-designed camera components met the rigorous requirements for filming and offered a modernized alternative for future film usage.

Related Content

New Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreMicro Robot Gripper 3D Printed All at Once, No Assembly Required: The Cool Parts Show #59

Fine control over laser powder bed fusion achieves precise spacing between adjoining moving surfaces. The Cool Parts Show looks at micro 3D printing of metal for moving components made in one piece.

Read MoreRead Next

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read MoreHybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

Read More

.png;maxWidth=300;quality=90)